I never thought I’d get to 20 visits. I’ve spent a lot of time at the plant. And I’m still not done. I always remind myself of how terrified I was on my first visit (I can relive it anytime I want by watching the video). Back then I didn’t know anything about coke or even the name of the plant. A lot has transpired since June 2020. And here we are today.

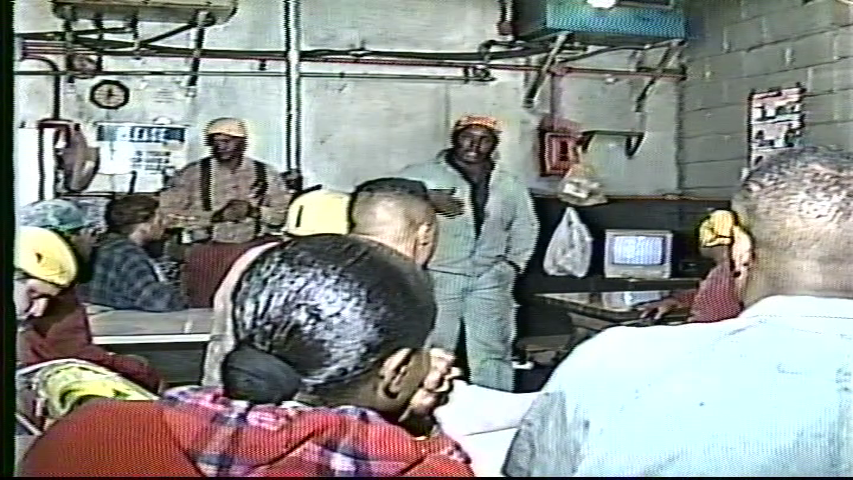

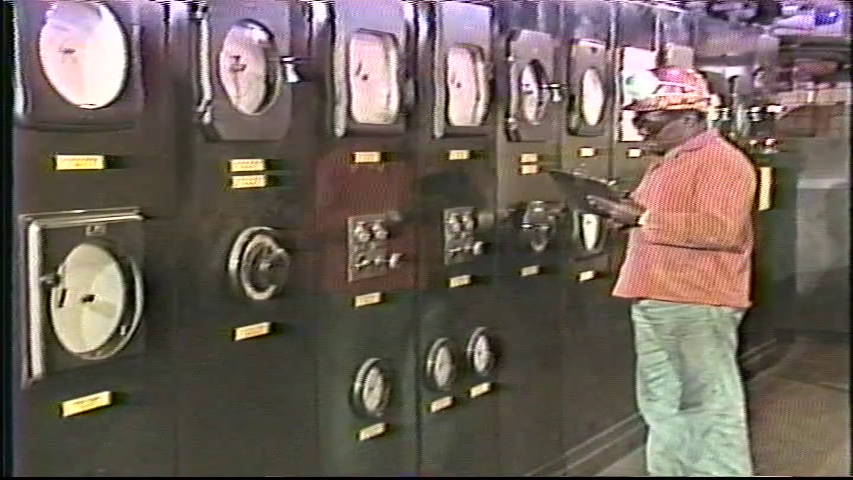

You have to pretend that you will be rewarded for your hard work in life. Optimism and visualizing your success gives you a reason to live, or at least to dig around in an abandoned building. About three months ago I found a folder filled with documents related to the commissioning of a training tape. Many nights I wondered what happened to that tape, or what that tape was like. Maybe it never even got made. Since then, I have met the owner of that office and last weekend, I found the tape. I knew that #20 would be a special morning but I don’t know if I could have visualized my success in this way. The tape was so crusty, the cardboard sleeve had totally disintegrated and creating a foul coating on the cassette. I tried to take it apart but some of the screws were so rusted I had to drill them out. I found a second tape also – I have still not yet gotten it to play but I am working on it. I have seen enough to know it is asbestos abatement training, and it is Acme branded. It won’t be as exciting as this, but it will still be greatly historic and I look forward to sharing it.

But before we get to that – what else of the day? I didn’t want to stay more than a couple hours so I decided that I’d hit up my usual places and only stay until I found something of value, then move on. This created a framework for a video in my mind and once I shot the necessary footage, I kept it moving and this kept me on my schedule.

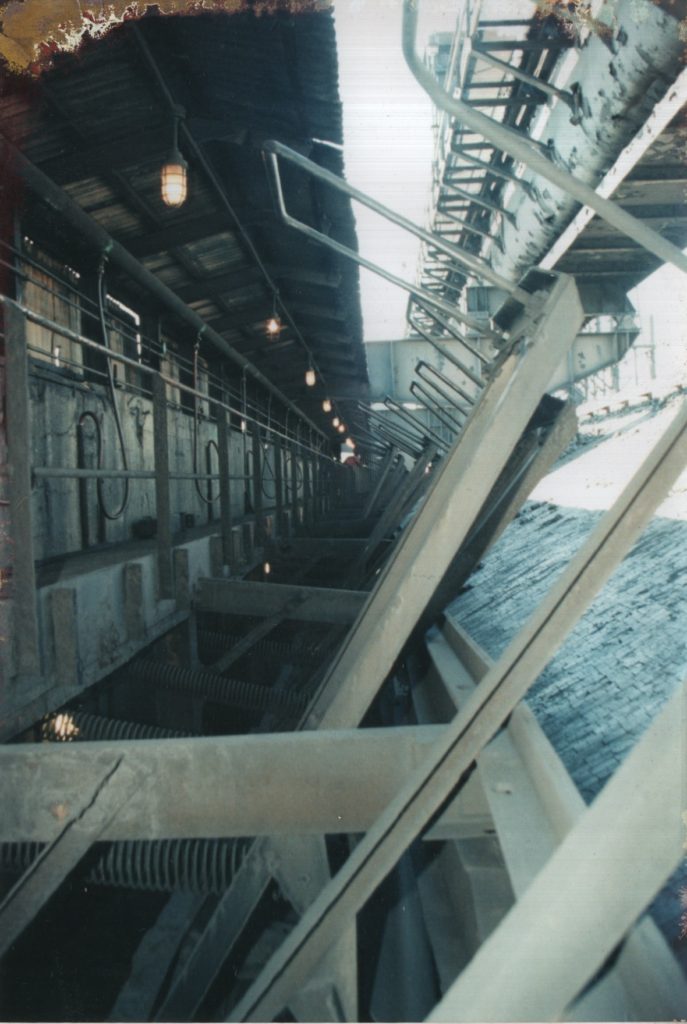

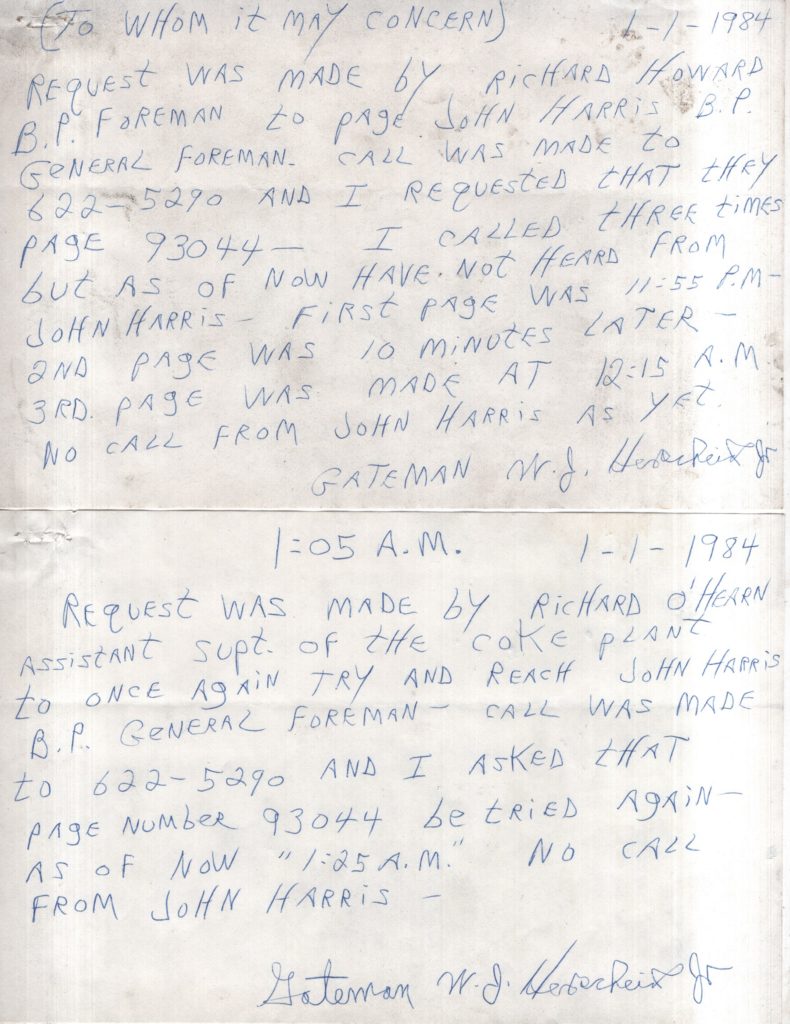

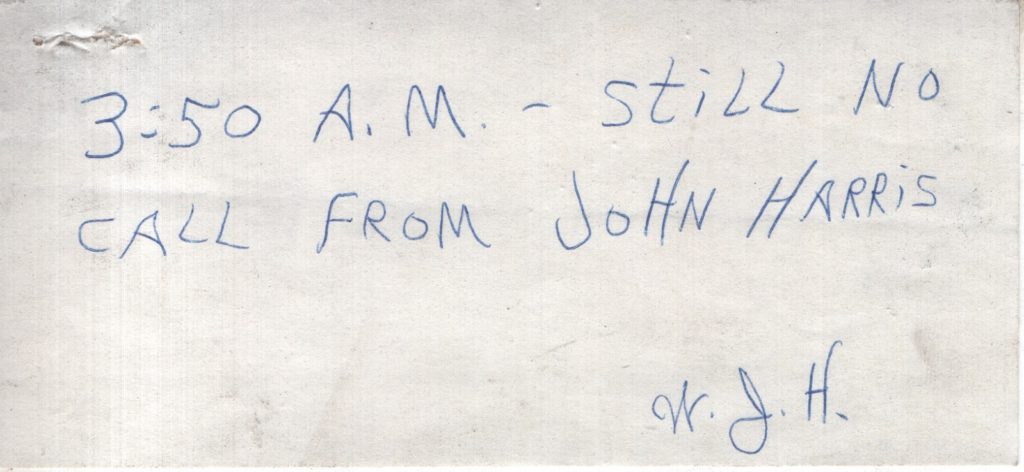

I found an envelope of developed color photos in Dick O’ Hearn’s office. They were still in the envelope from the development lab. The photos were all stuck together (there are at least 30) and the envelope was stuck as well. I picked the envelope off a little at a time, and when I got home I peeled all the photos apart. I really wasn’t sure what I was looking at though. I did see one that made sense, look familiar?

The background you see there is unknown to me. It doesn’t look like the battery basement (where I found the wrench) but I could be wrong. There are three others that are so odd I can’t even tell if they are upside down, landscape or portrait. So I did what any other lucky historian would do – ask an ex-employee! Of course I am fortunate to have my friend Doug to inquire with on the topic. His response is below the first photo.

Besides these four, the rest were extreme closeups of structural issues (as Doug described), so those weren’t worth scanning or even keeping. I did keep the four above however and added them to my permanent (physical) archive) with many other important documents and artifacts.

I had been hearing dogs or coyotes in the past couple weeks, or at least I thought I did. And I had been a bit shaken since visiting in winter and seeing the huge amount of animal tracks in the snow. I swore I heard some barking so I did grab an old 2×4 and I carried it as I walked from ovens to the coal handling office. I left it just outside the door on the north side of the building as I entered from the rear. I was just wrapping things up when I saw something through the east window. Yes indeed – it was a dog. And a very big one. I was very low on options of where to hide or remove myself from the situation and my makeshift weapon was stupidly 10′ away outside. I quickly got my affairs in order and began to prepare to get the hell out of there to….where? I don’t know. Then – another dog. Things were getting worse in a hurry.

I figured I might as well face the threat head on so I went out the back door and just as I was about to grab my lumber I saw a person. I assumed this was the dogs owner, but that still didn’t mean he had friendly animals. Once I took a few more steps he saw me so I put my hand up in a sign of peace. He returned it so I approached. His dogs couldn’t have given a damn about me so they were certainly friendly.

I ended up standing there chatting with Leo for a while. He said he lived on Ave. B and previously owned a business in Hegewisch. He gave me his card and I am familiar with the business but I won’t reveal it here so as to lend a friend some privacy. The large dog was a Rhodesian Ridgeback and I if I was a little smaller I could have literally ridden it like a horse. He shared my appreciation for the place on the most base level. Not for the history – just the peace. He said he had been coming around for much longer than me (more than five years). He wore a hi-vis vest to create the illusion that he was there on official business. I hope that I run into Leo again sometime soon. He said that when his time comes he wanted to come down to the plant and just take a nap under a tree and he said it without a tinge of sarcasm or hyperbole in his voice. A really good guy.

A quick run down of newly retrieved documents:

- “Coke Oven Walls Damaged by Carbonization Pressures” (1983)

- Report from Koppers. Appendix has case files on individual plants with Koppers ovens and damaged walls. An additional appendix called “Other Plants with Oven Walls Possibly Damaged by Carbonization Pressure” is dated 1953 and does list “Interlake Iron, So. Chicago, IL” but no additional information. A very good read and I’ve barely looked at it yet.

- No. 4 Coke Conveyor Structure Inspection (1992)

- Internal report on the coke gallery spanning Torrence Ave and the Calumet River on the way to the furnace plant at 107th. 10 pages of detailed notes on every defect in the structure than 9 additional pages of old drawings of the structure which span numerous pages. I may try to stitch them all back together into a very wide PDF.

- Chimney inspections

- #2 repairs (1994). Bids from Industrial Stack & Tower (Hebron IN) and International Chimney (they later inspected #2 in 1996 and gave it a good bill of health)

- #1 and 2 inspections (1992). Both done by Industrial Stack & Tower

- Phenol Removal Credits (1993)

- A joint appeal (Acme and their neighbor LTV) to request ‘credit’ (monetary?) from the water reclamation district for improvement of their wastewater quality

- Differentials & Temperatures (2001)

- Lightly bland checklists from BP plant most notable because the newest of the bunch is dated 11/5/2001 – VERY near to the close date of the plant

- Plastic sleeved sheets from area manager (ovens)

- (4) pages from Wilputte manual specific to the plant. References are to Acme which put it at post 1986. These pages are marked with the heading ‘DEFINITIONS’ and described general terminology around the batteries. A great primer for anyone looking to learn more about the ovens department operation

- (2) pages from another (seemingly older) Wilputte manual. One is marked ‘THE WILPUTTE UNDERJET COKE OVEN’ and has a very brief description of the battery with a longitudinal cross section. The other is a lateral cross section with no text.

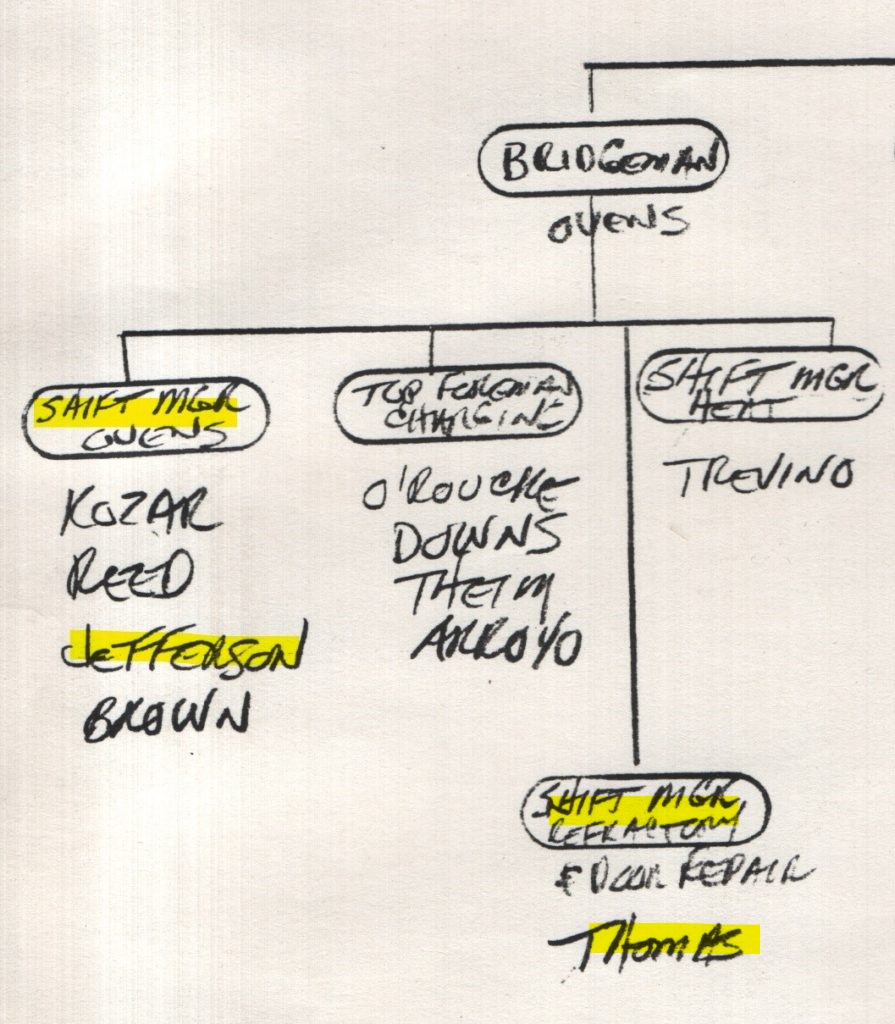

- Ovens department chain of command flowchart from area manager (Doug) down to heating and refractory managers, then shift managers and finally topside shift/assistant managers

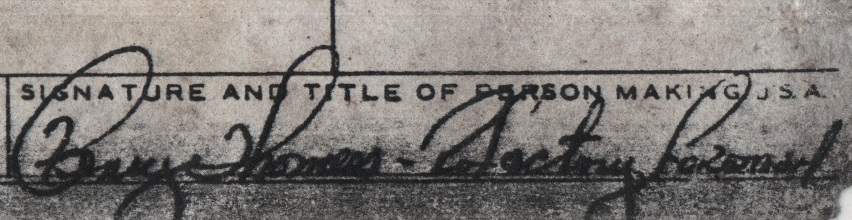

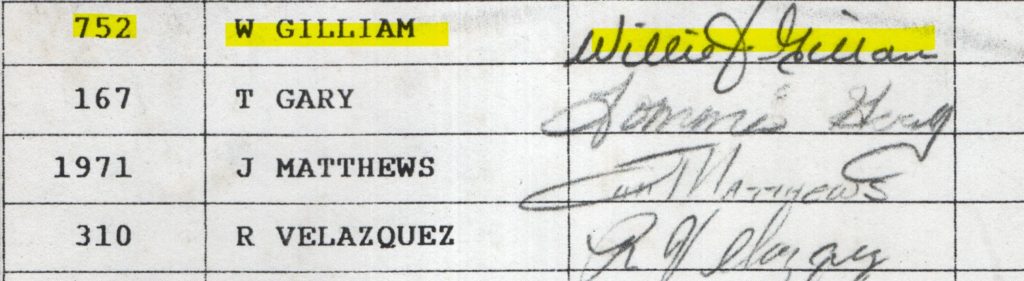

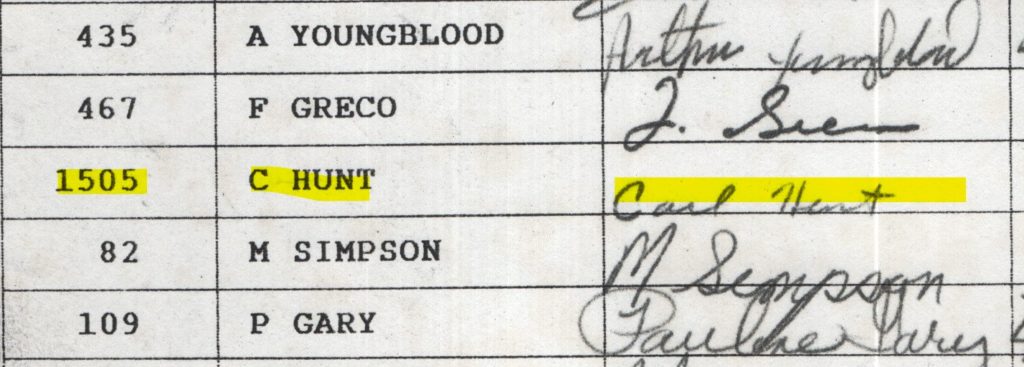

- Employee Safety Records

- These do not show a year, and all are specific to coal handling department. These seem to cover safety meetings more than accidents or times people needed to be reprimanded

Here are a handful of other documents that may never make it to the Document Archive but were worth scanning.

I am still undecided if I will go to the plant Saturday. I haven’t taken a weekend off in a long time. Even when I had to work, I sped over afterwards. I really wanted to get to #20 in case something happend (work travel most likely) that would keep me from the plant for a long time. I felt like something would stop me, I can’t believe I made it. But I sure have a lot to show for 20 days, and this video might be the best of all. Of course I enlisted Doug to identify anyone that could be seen in the video. I almost get goose bumps watching this and knowing who people are.

I realize now that I even found a rough draft of the narration and an outline for the video. I am beyond proud to have secured this relic and to be able to share it with the world. I hope you enjoy it as much as I do.