Slept poorly Friday night for unknown reasons but knew I needed to get myself up and at ’em. A big snow storm was in the works, so I knew I had to leave the plant by 2pm. I had two distinct missions for the day. The first was to get back into Dick O’ Hearn’s office and really go to work. I made sure to get some dust masks this time as I was hacking something awful last time. I figured if I worked hard for 90 minutes I could go through everything. My second mission was to get that standing desk out of there and into my truck.

I came in near the quench station and parked my bike. I stopped to quickly take an amateur stab at some graffiti as I walked toward the north end of the plant. I threw up a couple more Interlake logos around the south end of the plant as I walked toward the main office.

I ran into my boy FALS about 30 seconds later. We caught up and he came upstairs with me. He didn’t even come to paint – just to wander around. Have to respect that. I finally got to ask him where he found the banding tensioner he grabbed for me. He said he found it outside the coal handling office, sitting in the grass. I must have walked by it 20 times! I thanked him profusely for that and the paperwork he had stashed for me as I hadn’t had a chance previously. He went off to explore and I got right to my main task.

Things kind of just became a blur. I was finding some good stuff but I had a feeling of perpetual disappointment, as if something monumental was just under the next heap. I started making a landfill in the SE corner of the room, literally tossing junk over my shoulder, or putting it in the window sills if it required another look.

I found a few things that just didn’t make sense to take home to scan, though they were historically viable. So I snapped some photos and moved on.

I found a fairly thick AIST (Association for Iron and Steel Technology) directory. It listed all the members (companies) of the association, then each got a separate section listing some of the most important employees of each.

I neglected to get the third page which had the last few names. But Jack Garzella might be the only coke plant employee they figured was worth listing. I’ll have to have another look next time. I don’t remember the date either but I want to say it was the 1990s. The interesting part there is that Victor Beaucaire was an employee in the mid 1960s based on his authorship of the Tar Moisture report I discovered during my last visit – that is an impressive tenure!

Speaking of correspondence, I also found a very cool (but poor condition) envelope. It is hard to keep track when you have so much to go through – I swear I glanced inside and it was junk but the note written in red catches my eye now. I have a number of papers on this topic and I’d love to read more. I don’t remember even noticing that when I was there (seems impossible as it is written in red, but things get intense when you’ve been digging for an hour).

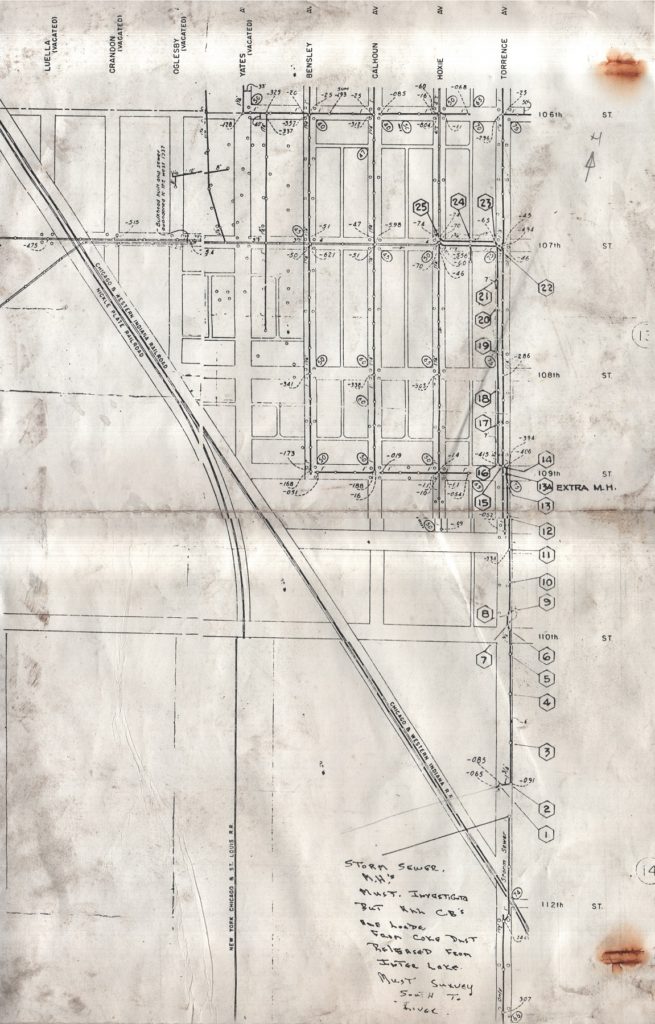

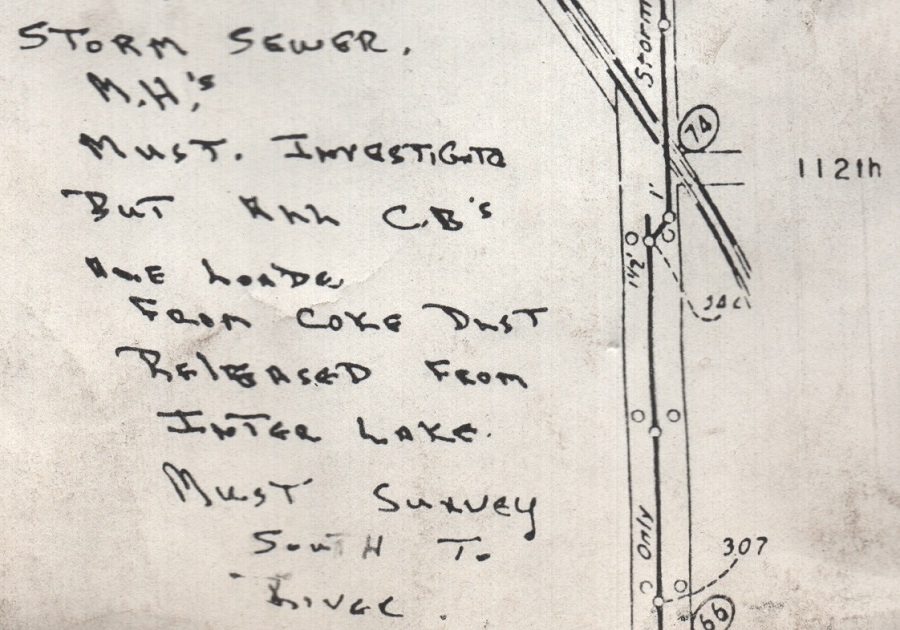

I do love maps, as I have discussed before. This one came with a business card from the City of Chicago Department of Sewers. This map largely shows the area north of the plant. The most interesting part probably is the descriptions of the various railroad tracks on the property. I have found evidence of the “Chicago & Western Indiana RR” line which runs SE near the lower right hand corner of the map. The rails are long gone but the ties are there, hidden in weeds. I noticed recently on Google Maps that you can see the continuation of this line on the other side of Torrence Ave. The handwriting at the bottom is difficult to discern but seems to say they found some coke dust in the storm sewer (not surprising).

But onto the many documents I hauled away. Probably spent more time going through them before I left than I have ever devoted before. Unfortunately I barely dented the total work required in this office. I’d guess another three hours would be sufficient but I don’t think I’d want to do that in a single day. So I’ll just continue to chip away.

Someone in clerical purchasing at Acme had a field day buying up these brown accordion folders. They are better than regular manila folders, I must admit. I have one I found months ago in the coal bunker which I bring with religiously every week to refill. I come across 10 or more every time I am in this office. Some are empty; some are filled but thin. Some are enormous but that doesn’t mean they hold anything of value. Well this one does!

It was at least 3″ thick but at least 1/3rd of that was duplicates. Either outright copies, or rough drafts, etc. So I spent some time Saturday night with a couple cold beers making piles on my floor. The real fun began when I found that I had brought something else home along with these documents!

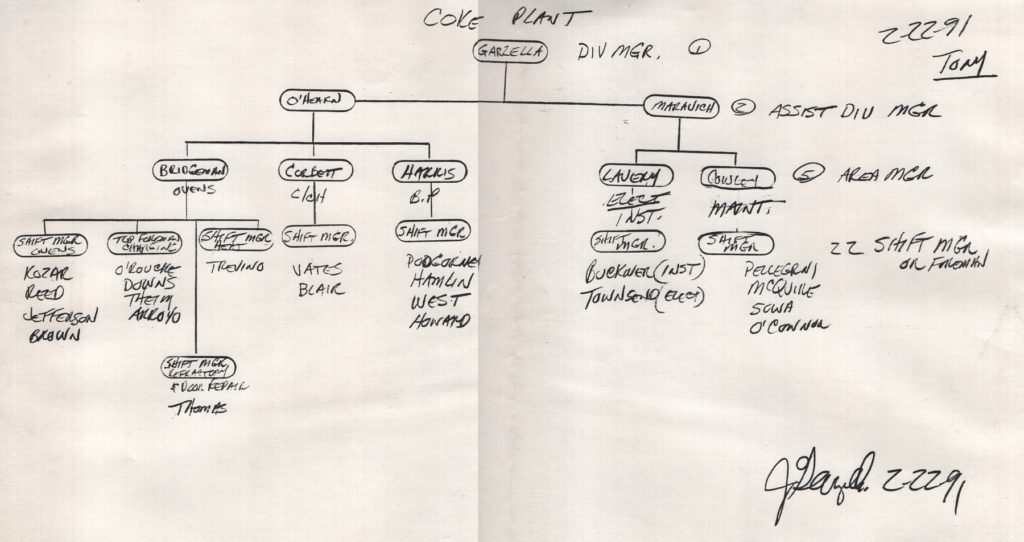

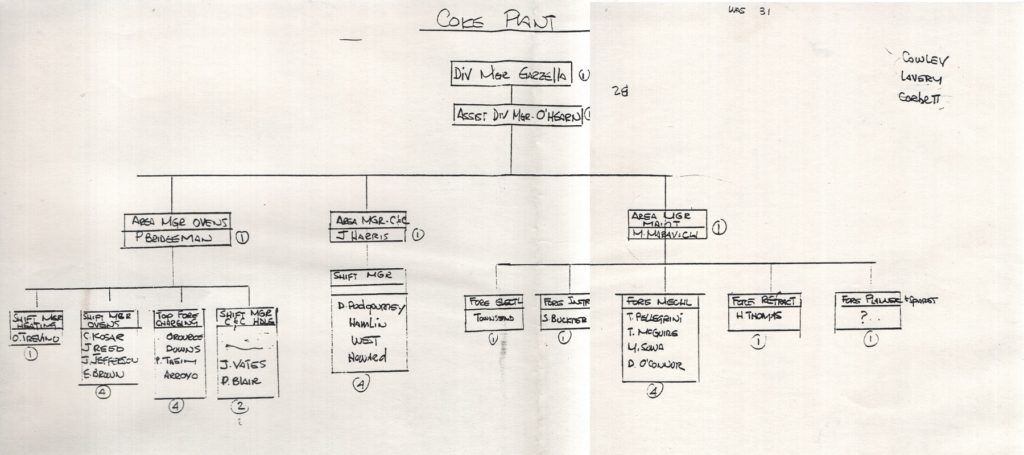

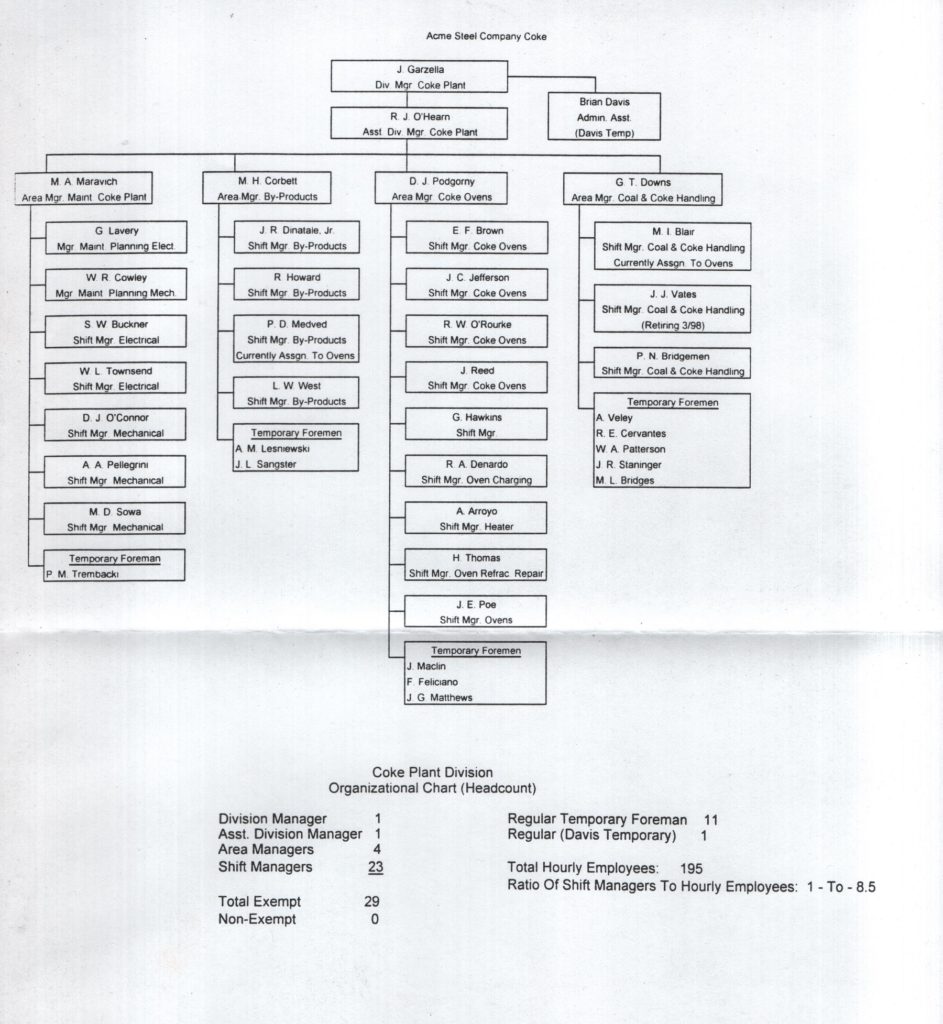

The many glass block windows in the office were long ago smashed, especially those on the north wall. I actually got a tiny shard in my finger tip while I was there, even though I was wearing gloves. This photo was taken just a moment after I extracted the piece and it quickly began to bleed more profusely. It must have fallen out of the folder and onto the floor where I eventually stepped on it. I hobbled to my kitchen to get a paper towel and apply pressure (easy when you can stand on it) then cleaned up the trail of blood and got back to work. Besides the multipage descriptions for each managerial position, it included three flowcharts demonstrating chain of command. Two are hand drawn and older but the last is drawn on a computer and (I believe) the last crew the plant had before it closed.

“The Story of Coal and Coke Chemicals” is a really fun pamphlet that is so straight forward it almost seems to be aimed at house wives. It is already scanned and can be found on the Resources page. Some people read Playboy and they can’t wait to reach the centerfold. I read a different type of periodical, with a different type of centerfold, but just as titilating! My copy is a legitimate bootleg and has been Xeroxed. I did find the real deal sold elsewhere on the web.

As for the many reports and other documents I found…these are all scanned in the Document Archive.:

- Baker Petrolite BP proposal (1998)

- Seven page report recommending an array of chemicals to treat Ammonia, tar and COG – with an annual cost of [SPOILER ALERT]

- Wilputte NH3 effluent data reports (1992)

- 10 pages – hard data as only Wilputte can do it. Seems to be measuring ammonia content at various places in the by product plant.

- Complaint/Grievance Forms (1999, 2000)

- Some of the more entertaining reading I’ve come across, I look forward to publishing this soon.

- Interlake purchase orders (1973)

- A nice counterpart to the 2001 Acme POs I found recently. Most interesting were a couple POs to different railroads. Funny because I was selective in what I took home and also what I scanned when I grabbed the Acme POs, of which I had very many. But they were all very innocuous – boring purchases from boring vendors. But in only a small pile of these Interlake POs I found some really good ones. I hope I stashed the rest where I think I did so I can get more next weekend.

- “Oven Daily Report” (2001)

- Data seen previously on the different incarnations of the ‘Morning Reports’ I have found more than once. These however are much more oven-centric and make no mention of coal blends, etc. Most interesting is the designation that considers anything above 200A required by the pusher as a ‘hard push’, and has another box for 250+. Looks like as much as 50% of pushes on an 8 hour shift than are considered to be ‘hard’. An aging battery contributed I am sure or fickle coal blends. There is also a box for some measurement of the HKC system but no unit of measurement is given, very intriguing.

- “Battery Span Temperatures” (1981)

- Temperature readings at PS and CS for every oven in the battery, plus adjacent flues for an arbitrary oven, and graphs for these flue readings. Done daily, for each battery (6 pages per shift, 18 pages per day).

- Emergency Major Repair Project Authorization (1997) to repair HKC duct fan

- Brief single page purchase requisition with explanation. I am going to publish this as part of the HKC duct inspection I found last week but did not publish. I wasn’t going to scan that because it was bound in a folder, but I just yanked it from it’s binding.

- Wilputte Battery inspection report (1994)

- Brief five page report that has the tone of a doctor telling a guy who’s been eating Big Macs for years “you aren’t going to die today, but you won’t live long unless you start making changes”.

I am starting to accumulate a serious archive of large technical drawings! Keep in mind I already found two in the coal bunker showing flue thickness measurement (for both batteries), then last week found two more for the HKC duct. I hit gold and found quite a few!

- “General Arrangement of Proposed Spiral Heat Exchangers – Light Oil Cooler Area”

- 1969

- designed in house (Interlake)

- includes separate reports describing proposed work

- “Upgrade Temperature Control of Heat Exchangers”

- 1996

- designed in house (Acme)

- “BF Gas Regulator Arrangement and Piping”

- 1955

- designed by Wilputte

- “BF Gas Main to Ovens Arrangement”

- 1956

- designed by Wilputte

- “BTU Control – Blast Furnace Gas to Coke Ovens”

- 1969

- designed in house (Interlake)

- “Steam Piping TB to Battery T5 Arrangement”

- 1957

- designed by Wilputte

- “Ammonia Still System Vessel Arrangement”

- 1989

- designed by Dravo

- includes report from Orbital regarding structure inspection (interesting that Orbital had access in 1985 to a drawing that Dravo did in 1985)

- This print is in rough shape – has some water damage at the creases and once I unfold it, that might be the last time.

So as last time, since it is not possible to scan these very well, again I will have to make a video showing them as best I can.

And with that I was left to my final mission, to move my standing desk from the ovens (general) area to the fence line near the quench station so I could pick it up on the side of the road and bring it home for it’s rehabilitation. Remember that last week I moved it from the BP office to ovens – a back breaking routine that nearly gave me a heart attack. Well this time wasn’t much better, my bad night’s sleep had begun to catch up with me at this point, along with the cold weather seeping into my bones. But I did get it over there somehow.

You can even see the tire tracks from when I arrived hours before through this same passage. Things went according to plan, I am glad to report. I decided to forego my usual lunch of reflection, with my sandwich from Baltimore F&L to save time with the snow pending. I grabbed my grub (along with some whiskey and FFF for the coming snow-in that evening) and went straight back to Torrence without taking a bite. Coming from the south, I made my turn around in the bus stop just north of the gate house. Traffic was largely non existent and I moved quickly. I was pleased to see that I was able to get it into the bed of my truck sideways (it’s height did not exceed the width of the bed) which saved plenty of room for my bike. Afterwards I pulled off into the small Indian Ridge Marsh parking lot for my long awaited lunch.

Worthy of note that besides FALS, there was a couple wandering around, FALS gave me a heads up. When I went to leave, I saw a group and figured it was them but it wasn’t. A trio of friends. I showed them how to walk the plank up to the second floor of the main office. They better not have disturbed the contents of my office! Next weekend should be a cold one – but I’ll be ready!

4 replies on “Saturday the 13th”

Still hard to believe you jumped that heavy fucker as far as you did, can’t wait to see the restoration. Get some neosporin on that wound!!

I can’t believe it either- I’ll be reminded every time I look at it. First coat of oil goes on in about 12 hours. Can’t wait. And I’ll have to bring a first aid kit for sure!

Hi! What a great archive! I am looking for an employee that wokred for wilputte whom I think worked at the site you re investigating. This would be about 1939-1940. The name is Cirrincione or Cirricionne (no “n”). Any insight greatly appreciated.

I will send you an email now!