Bitterly cold morning, but not nearly as cold as it could have been. I think it was around 15F by the time I got to the plant but I was well dressed and ready to go. As usual I came in around the quench station. It might be questionable to do so when I intend to spend all my time in the main office, why not bike further north and come in through the gate house?

- There aren’t nearly as many places to lock up a bike as it might seem. Further south the plant kind of reverts to wilderness and there are plenty of sturdy saplings of a suitable diameter to lock to

- Even locked, I’m not fond of leaving my bike alone when others might be wandering around. Given the childish tendency toward destruction of most visitors, I don’t feel like someone letting the air out of my tires or worse. But back there, there is much less foot traffic.

- I like approaching the main area of the plant from the south, kind of like being in a corner so you have the best view of everything around you. If I come in through the gate house, everyone can see me enter and might be watching. If I approach from the south, I’ll see anyone as I head north.

The only thing I did not anticipate with this is the snow being deep enough to make walking all the way a very tiring endeavor. I knew that when I left, I’d go out through the gate house and walk down Torrance to get back to my bike.

I wrote a quick note to myself before I headed out, four things I wanted to grab:

- Binder

- Disks

- Wages Book

- Interlake POs

#2-4 are discussed below; #1 was a reminder to grab an empty Acme Steel binder. The one I have is getting full and the spine is partially cracked. I know there a number of spare binders in the asst. division managers office. So I did grab one which was already empty. This time I was careful not to open it. Besides being literally frozen, the plastic is very old and brittle. When I tried to open the binder my business cards were in, I cracked the cover clean off. So I am going to look into getting some plastic rejuvenator/restorer. A binder has to bend so it needs to be supple and I intend to use this, not restoring it ‘just because’.

Spent at least an hour in the office, time always goes by like a blur. I brought a Thermos of tea to keep myself warm, something I’ve thought about a few times but never did. Made the morning more pleasant for sure. Came out of there with a pretty serious pile of gold. Took me over an hour to go through it all and write up detailed descriptions. It is important that people see I am curating what is on this site, not just grabbed random piles of junk and scanning them. I am at the point that I can identify very quickly what I am looking at, for very technical things I might not fully understand but even then I have a semblance of how useful/entertaining/important it might be, before I even look close.

- 1986 USW Agreement

- I grabbed this last week and just took a couple photos of the cover and TOC. It wasn’t until I got home that I realized the ‘Wages’ section of the manual might be interesting. Luckily, I did leave this tiny book in a smart place that it could be found again. I grabbed it and the wages section required additional research which will warrant it’s own post

- “Coke Batteries Heating Practices and Guidelines” (1987)

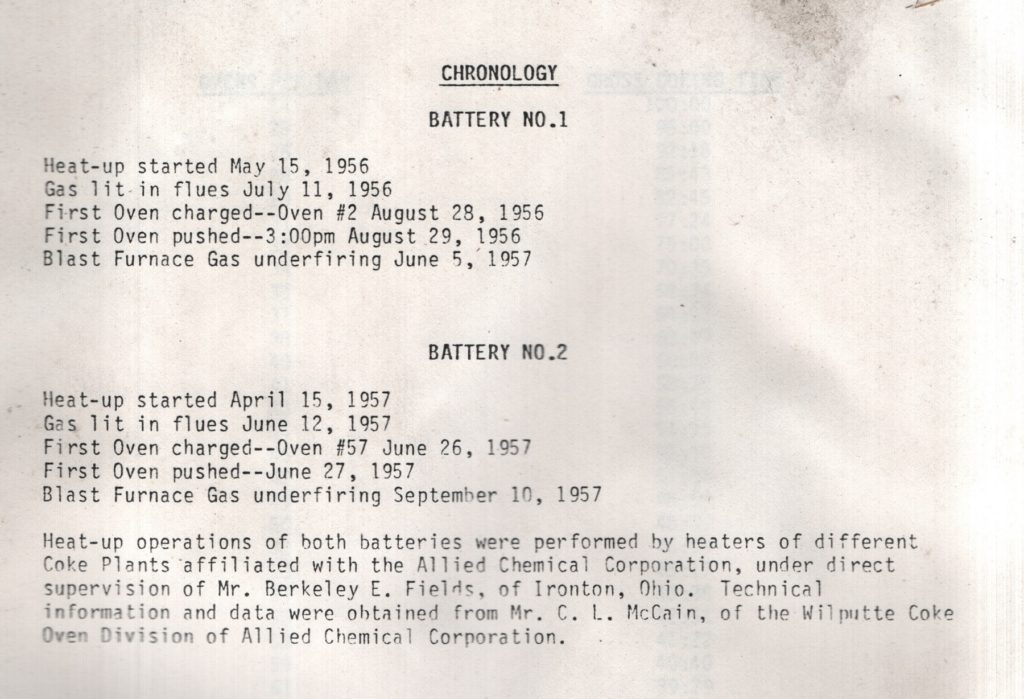

- A number of the most important documents I’ve ever gotten my hands on were found in plain sight. This one is part of that lot. The bright yellow cover caught my attention and as soon as I picked it up I knew it was in great condition. It had to have fallen or been tossed down from upstairs which is odd given how important this is. Unfortunately much of it is boilerplate (like sample pushing schedules, pages and pages of them). But the very first page marked ‘Chronology’ is so historically important it can’t be stressed enough. Some of the rough dates I already knew but to have it written down in plain text is just amazing.

- “Coke Plant Injuries (Fiscal)” (1988 and 1989)

- I have mixed feelings about these. It isn’t right to get excited about people getting hurt. But it is at least interesting reading in that it describes injuries and it lets me try to imagine the conditions these events occurred in. The plant went from 52 injuries in 1988 to 20 in 1989 – not bad!

- Daily Maintenance Reports

- Found just two of these, from 04/11/89 and 9/21/89. These caught my eye because they are broken up into headings for each department (ovens, CCH, etc). I’d love to find more of these and I hope I do.

- Maple Meadow Mining – Sample lab tests

- The fax cover sheet is at least as cool as the content. Interesting because I know they bought their coal through ‘coal distributors’ (mineral companies), and MM coal through AMAX, but this data comes direct from the mining company in West Virginia.

- Interlake POs (1973)

- I was hoping to find more of these, grabbed a stack last week. I could not find the folder I left behind no matter how hard I looked but then I did find a NEW folder with more, but only a few. These are the pink carbon copies but still very readable. I have been in touch with some local rail fans, who specialize in short line rails. I shared some of the POs I found last week and I found two more here, and these are for a different rail company! I’ll be sending them these tonight. I was already told they would be part of their next newsletter, look forward to sharing that here.

- Battery top reports

- Kind of three versions of the same thing, never seen any before. They span a great deal of time but they are very readable given my focus on lidmen training not long ago.

- Top Supervisor Report/Top Foreman Reports (Nov. 1996)

- Oven Top Shift Manager Reports (Jan 2001)

- Oven Top Report (April 1981)

- Kind of three versions of the same thing, never seen any before. They span a great deal of time but they are very readable given my focus on lidmen training not long ago.

- Accident Report (1998)

- The harrowing tale (written long hand, on notebook paper) of a door cleaner who took a piece of refractory brick to the shoulder and lived to tell the tale! Despite the investigative process his medical care consisted of….asprin! (Seriously)

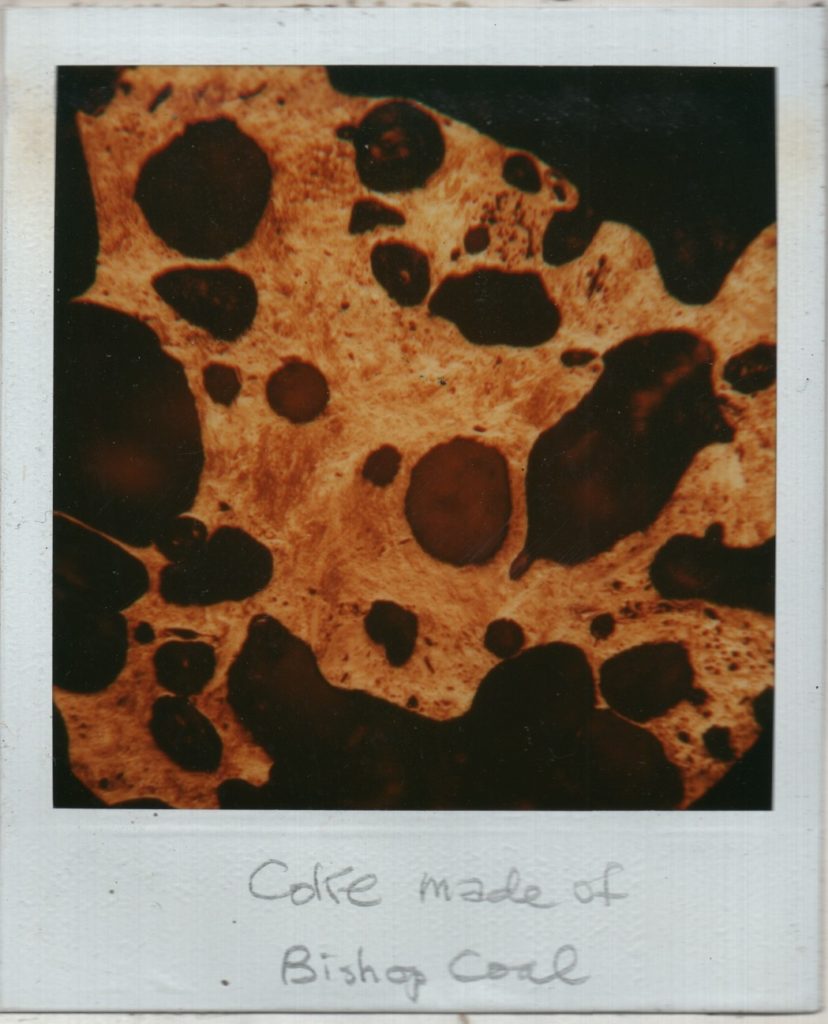

- “Use Of Petroleum Coke in Cokemaking and it’s Evaluation Through Coke Petrography” (1984)

- I know what you’re thinking: I’ve already found this. True. I even found the programs from the Steelmakers conference where this presentation was given. What I had NOT found was this wonderful specimen! I have not been in Dr. Lin’s office in weeks as it is mostly barren. But it was so cold I had to move around to stay warm so I wandered back there. And again, this was laying in a place of prominence, waiting for me to grab it. This is the original copy (it is bound as well) and has the original Polaroid photos taped inside! The copy I scanned has only Xerox copies of those photos. This version is from the previous year relative to the version I have posted now. I don’t want to disassemble the binding so I am going to scan the pages with the color photos as well as the appendix (not present in the 1985 version) and have it as a separate PDF ‘addendum’.

- “Specification for the Remodeling of a Lunchroom at the Chicago Coke Plant” (1983)

- Kind of a fun document from what must have been a good era at the coke plant. You aren’t worried about going under when you are building new facilities for your workers.

- Union correspondence (1991 and 1992)

- Letters from the aforementioned years to the union and some contractors regarding an alternate entrance on 116th Street presumably because there was some kind of picketing going on at the gate house.

- Coke Oven Door Test Program (1991)

- A quotation to supply two each CS and PS doors from a Japanese manufacturer (to be supplied and installed by a company in Michigan) to the tune of $64,000 (bear in mind the plant has 200 doors, not counting spares, and this is for four of them). In an attached letter they also show interest in quoting 220 doors (to replace them all, plus spares). Do the math on that one!

- No. 1 Flushing Liquor Decanter Tank Inspection

- Very nice bound report on the above, includes some folded drawings at the end. Slightly damp still, this will need to dry out some before I dare touch it, much less try to scan it. A common problem for documents bound with plastic covers which holds moisture inside.

- “Methods to Downsize Foundry Production” (2000)

- I’ve touched on the plant’s move to foundry coke (as opposed to furnace coke) in the waning years of the plant’s history. This packet is largely pushing schedules aside from the first two pages but historically an important chapter regardless of content.

- “How to Use U.S. Coals in Cokemaking”

- This appears to be the final draft of a report I already found the rough draft of (“Addition of Western Canadian Coal and Petroleum Coke Into a Predominantly U.S. Origin Coal Blend”). Still have to compare the two documents more closely to be sure but seems to be the case. This version has drawings and photos included. It also has another shorter report titled “Selecting Coal Blends for Coke Making” and a one page list “List of Out of Service Tanks” stapled to it. Put the stapler down, sir!

- “Cancelation of Acme Purchase Order 24-46616-95” (1995)

- The tone of this fax is so much fun! It seems that Acme ordered some coal from Carbon Processing & Reclamation, then canceled it. I wish I knew how much the PO was for but I’m certain it was a large amount. The vendor replied with a three page memo explaining why the reasons Acme gave for canceling were invalid (all are concerned with coal quality). The cancelation fax is also included. Great reading!

- “Coke Oven Flue Temperatures” (1994)

- Internal memo regarding lowering flue temperatures so the plant can move to a lower 99 ovens/day pushing schedule. This includes a massive packet of data from Dr. Lin (I know his handwriting at this point, and he’s mentioned in the memo). Dr. Lin went through morning reports for FIVE YEARS, then re-wrote the flue temps on new paper. Imagine if this was accessible via a spreadsheet!

- “Punch List – Coke Side Bench Repair” (1998)

- Quick two page memo regarding the above repair for CS at ovens A7-A13.

- Oven Dept. Sticker Report (1999)

- Never came across these before, grabbed four of them. I just did some reading on the AIST website about stickers (jammed ovens that will not push) so this is very interesting for me. Two of the reports include a few pages of crosswall temperatures which is an interesting immediately move toward finding root cause. Excellent stuff.

- Oven Expansion Measurements (1959)

- I took photos of this envelope last week but didn’t really look inside. I don’t know why that is, and it wasn’t until I got home and looked at the photos that I saw it was written in some kind of red crayon “OVEN EXPANSION MEASUREMENTS” on the front. So I planned to grab it or at least look inside. I know of the pitfalls of coal expansion during the coking process (which can damage oven walls). But this is regarding expansion of the entire battery! All the documents are from 1959 and early 1960. All of it is regarding structural analysis (physical measurements) of the batteries. They actually ran a wire around the batteries, to use as a fixed reference point to measure to/from various structural elements. I found this photo that helped clarify things for me:

- There were lots of extra copies of memos and many of the pages are mimeographed on very thin paper which is hard to handle. Some of the memos originated at the coke plant, others at what must have been corporate headquarters in Cleveland. It took a while to collate it all, get rid of what is redundant and put it in order. There were even pieces of scrap paper with random calculations on them. The finished PDF for this will be something I’ll be very proud of.

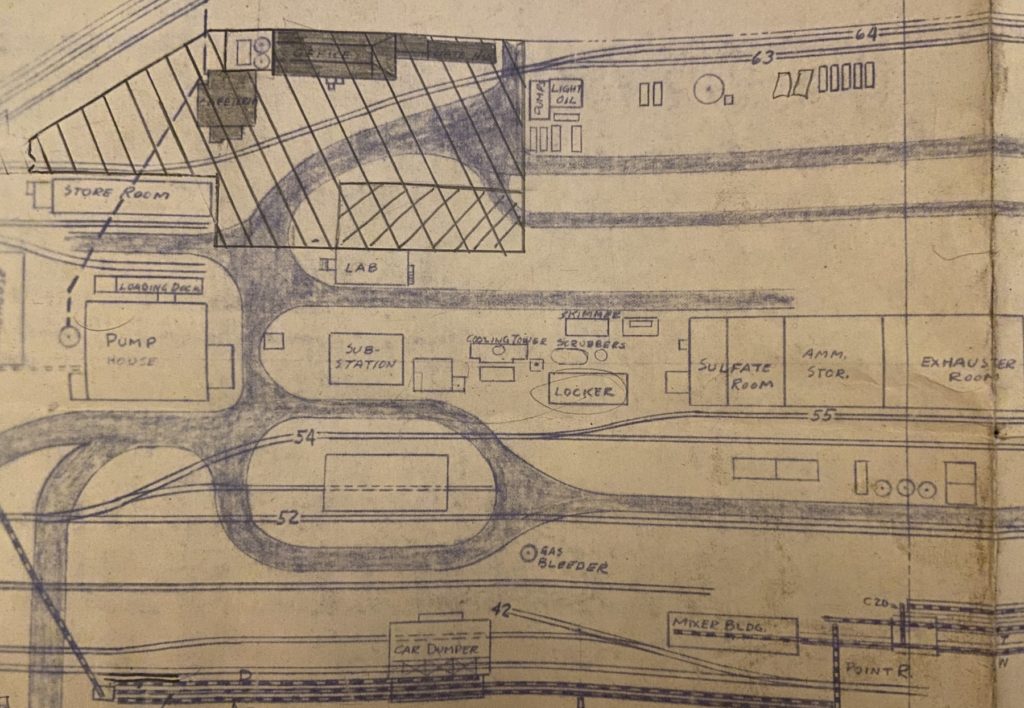

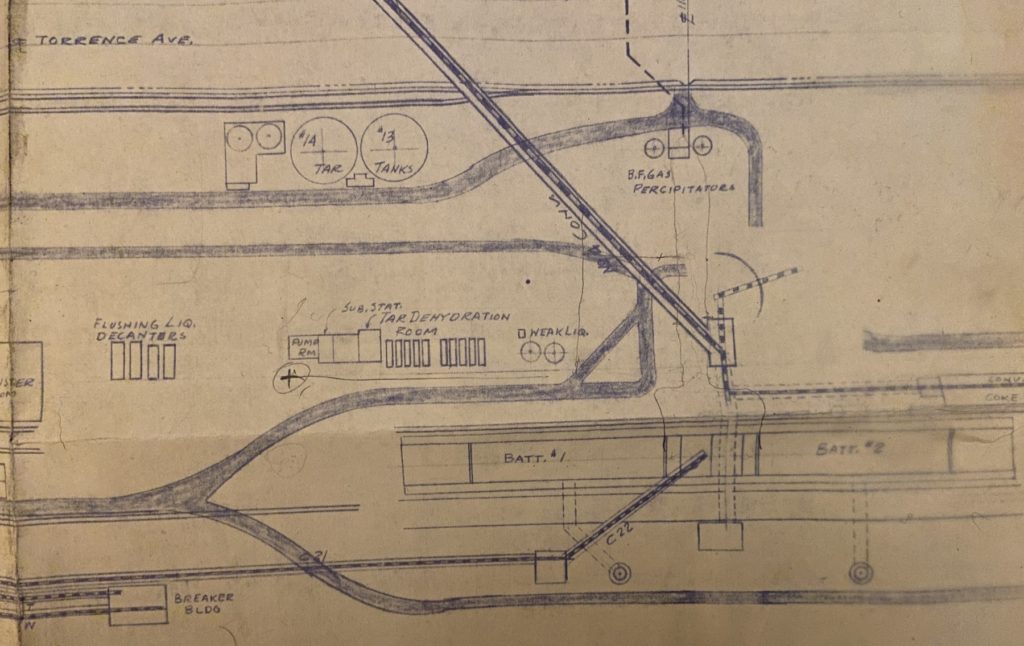

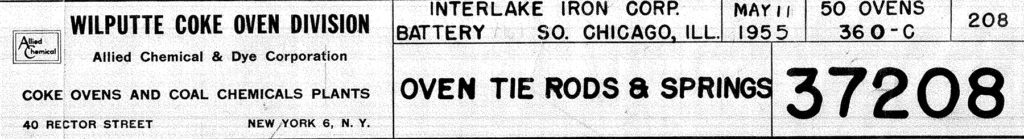

- Blueprints/Drawings

- Before today I had 8 sets of drawings. Most are a single page, some are two related drawings I found together. After today I have 17! One from today is actually just a map or general layout of the property (it is undated). Unfortunately some of it has faded but it is still pretty amazing. It does show Wisconsin Steel across the street which puts this at pre-1980.

After calling a number of places regarding scanning, I had two outright refuse. One wanted $250, one was about $175. Then I found another for MUCH cheaper and I shipped him all 17 prints yesterday. Already today he had them all scanned! I don’t have the files yet but I do have some PDF proofs. Amazing resolution – stay tuned!

- Disks

- After I found and (probably) ruined the disks from the coal handling office, I knew if I found more I’d be more careful. I had continued to find many in the asst. division managers office and stacked them on a window sill. I planned to finally grab them all today. I have low expectations because based on the labels, they are all software and not data/files. As soon as I arrived, I could tell that humans had disturbed my mess and the disks were gone except for a few that were unlabeled (and probably blank). I later found some on the floor in the mess, not sure if they were some of those lost or new ones. At any rate, I grabbed them all. Unfortunately, it is pretty obvious based on the labels that these are install disks for software, so they shouldn’t contain any data from the user. Still, I cleaned them up as best I could to take a look. I tried to pop one open to really get some canned air inside but I might have compromised the case enough that the drive has an issue with it. I had seven more besides that one and I did get one to open! Of course it is just part of a program file (the software was spread across multiple disks) but at least I got to peek at the properties

- Brochures

- Full color promotional literature for a variety of oven hardware

- “Refractories for Coke Ovens” (OCL, India)

- “From Coke Oven…To Caster” (Enprotech, USA)

- “Ikio Diaphragm Type Coke Oven Door Model -I” (Ikio, Japan)

- “Ikio Diaphragm Type Coke Oven Door Model -II” (Ikio, Japan)

- “Coke Oven Door Extractor” (Ikio, Japan)

- “Chemico Hooded Quench Car System” (Envirotech, USA)

- Full color promotional literature for a variety of oven hardware

I did take another glance at that American Iron and Steel Institute directory I mentioned last week. I hadn’t checked the date but I see now it is 1995. I also checked page 3 of Acme contacts (which I did not photo last time) and again it was mill or corporate personnel, no one from the coke plant.

I also grabbed the Interlake ‘Primary Safety Program’ from 1972 which I showed last time. Pure boilerplate through and through but a fun piece to add to my personal archive and small enough that I don’t mind stashing it.

I didn’t take any other photos but I took a couple videos, here they are all put together.

One final and eerie note. When I came through the fence near the quench station, I always have to swerve across Torrence as I am headed north but need to enter on my left. Luckily there is never much traffic (literally none) on Saturday mornings so I glance over my shoulder and when I see no incoming southbound traffic, away I go. I was confused because I could see some kind of white vehicle up ahead in the right lane (southbound). I hesitated at first so they could pass but then it began to look like they were parked. I figured I had time to get over and I did just that and thought nothing else about it.

As I said when I entered the plant, I planned to leave out the gate house and walk down Torrence so I didn’t have to trudge through 6″ of snow on the long walk back. As I walked back south I realized that the white vehicle I saw was up ahead. On my bike, I was sure it was south of the gate house. But here it was, and it hadn’t moved in at least an hour (the time I had been inside).

I approached carefully because I wasn’t sure if anyone was inside, but I did see that it was not running. Turns out it was indeed just as abandoned as Acme was. I peered inside and saw some interesting documents on the dashboard. It was a letter from ICU Monitoring, the firm that Lake County Indiana uses for home detention anklets. Signed and dated 1/27/21. If you wanted to just ditch a car, this would be the place to do it. If I had thought of it, I’d have felt the hood to see if it was still warm. The vehicle is seen at the end of the video above.

When I climbed down from the 2nd floor of the main office and headed to the gate house, there were fresh footprints heading in from Torrence. They didn’t use the front door, they came in through the driveway, headed toward the main office then turned south toward ovens. I looked around but didn’t see anyone. A cold day for exploring but any day is good if you just need to be alone, and Acme is the place to do it.