My first plan of attack was to head back into the BP office and continue to dig through the frozen landfill I have been neglecting for months. I found a big plastic bin as well which I brought back to the main office. I had been wanting to try to offload junk from the asst. division managers office to the adjacent office across the hallway so that I could actually search through what is left more easily. I must have carried 10 loads across the hallway. I do think it helped, I found some great stuff and I probably almost found it in weeks past, but it is just too hard with such bulk in your way. Here are the main scores:

- 1977 section main inspection

- memo, plus 2 page report and 12×18 drawing

- 2001 larry car volumetric control

- includes memo, bar graph, and 6 drawings

- 1997 acid tank upgrade

- two drawings

- BP docs

- misc binder

- binder of mixed BP docs, including hand written notes. binder was badly water damaged but documents are intact. docs describe shut down/start up of various BP plant tanks/vessels/pumps/etc

- 1995 light oil facility training

- part 1 (46 pages)

- 20 pages of diagrams

- part 2, questionnaire (20 pages)

- part 3, quiz (7 pages)

- part 1 (46 pages)

- 1997 “procedure for BP operators”

- 4 separate procedures

- misc binder

- “atmospheric corrosion protective coatings for the coke oven gas bleeder stack at the chicago coke plant” (1978)

- mint condition, interlake research center spiral binding

- also includes 1978 bleeder stack inspection report (I just found the 1976 report for same last weekend)

- hard pushes memo

- memo from fording coal on their advice on how to avoid

- includes 3 memos

- chicago plant accidents 1997

- 2 pages, includes furnace plant

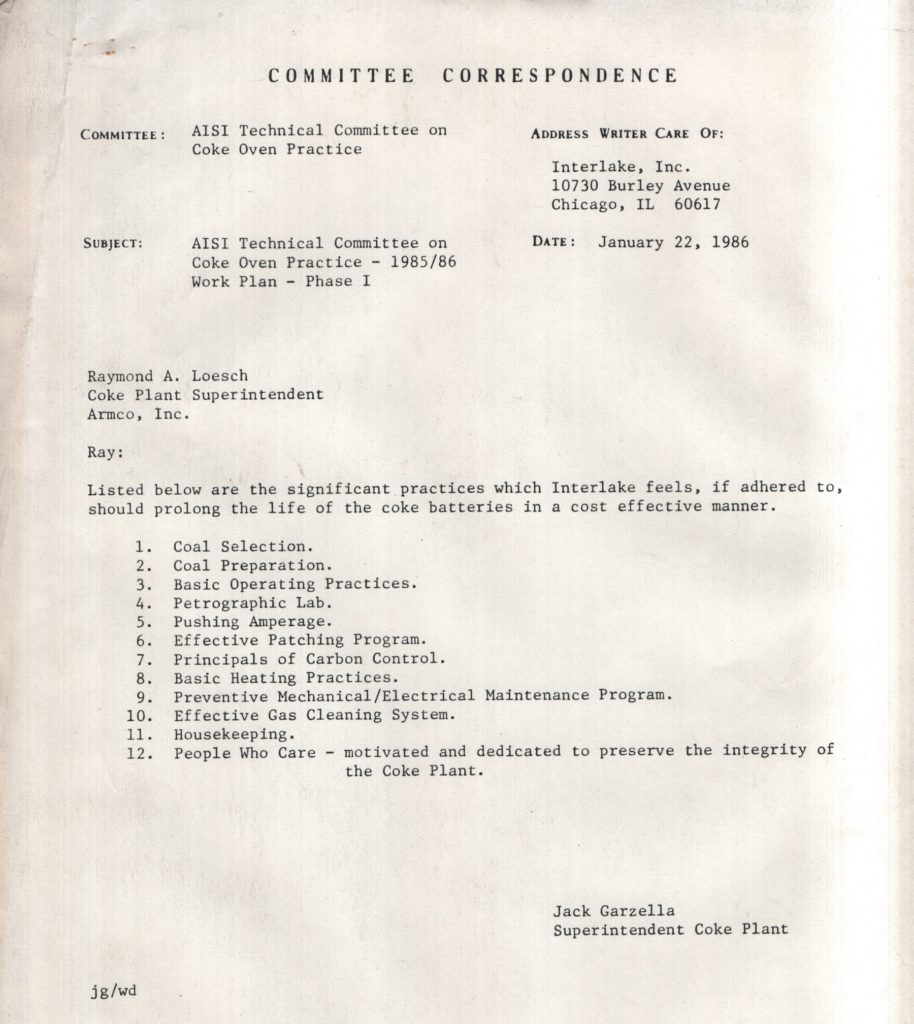

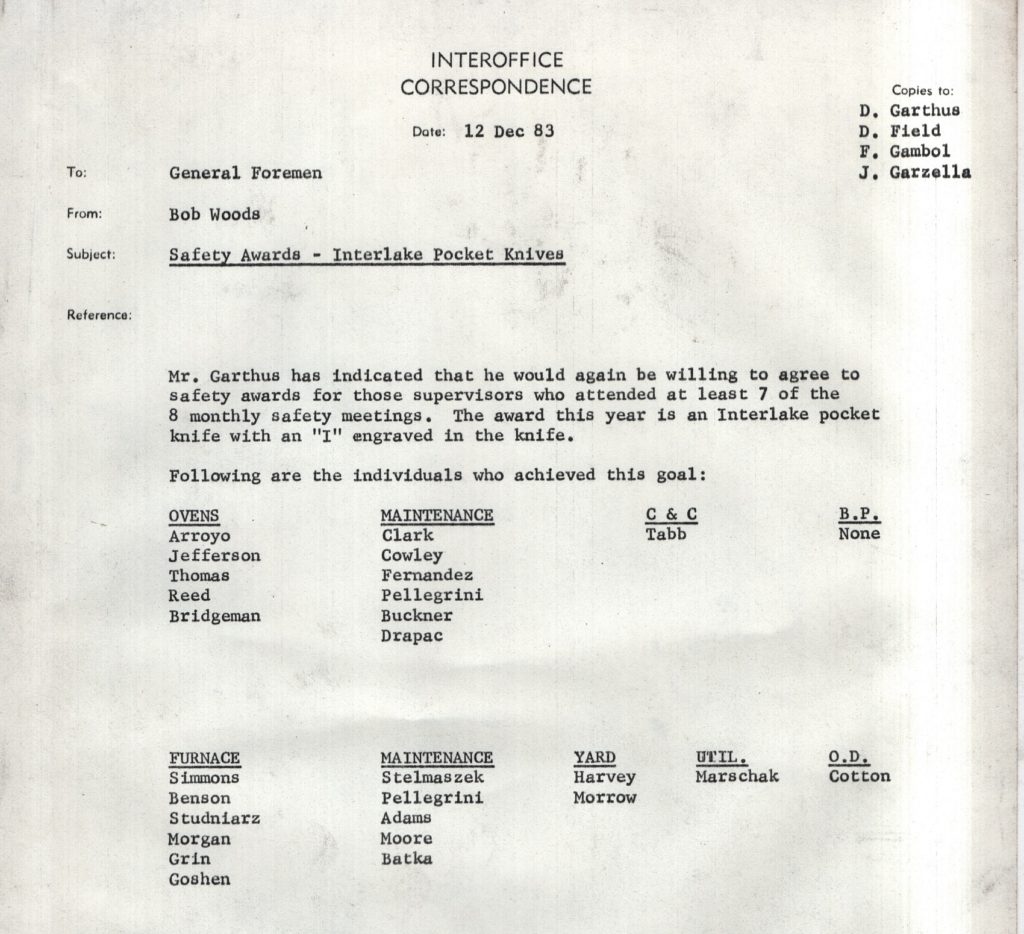

- 1986 AISI technical committee memos

- three man committe included coke plant division manager

- 2000 enspect, mill water pump inspection

- includes 12×18 print

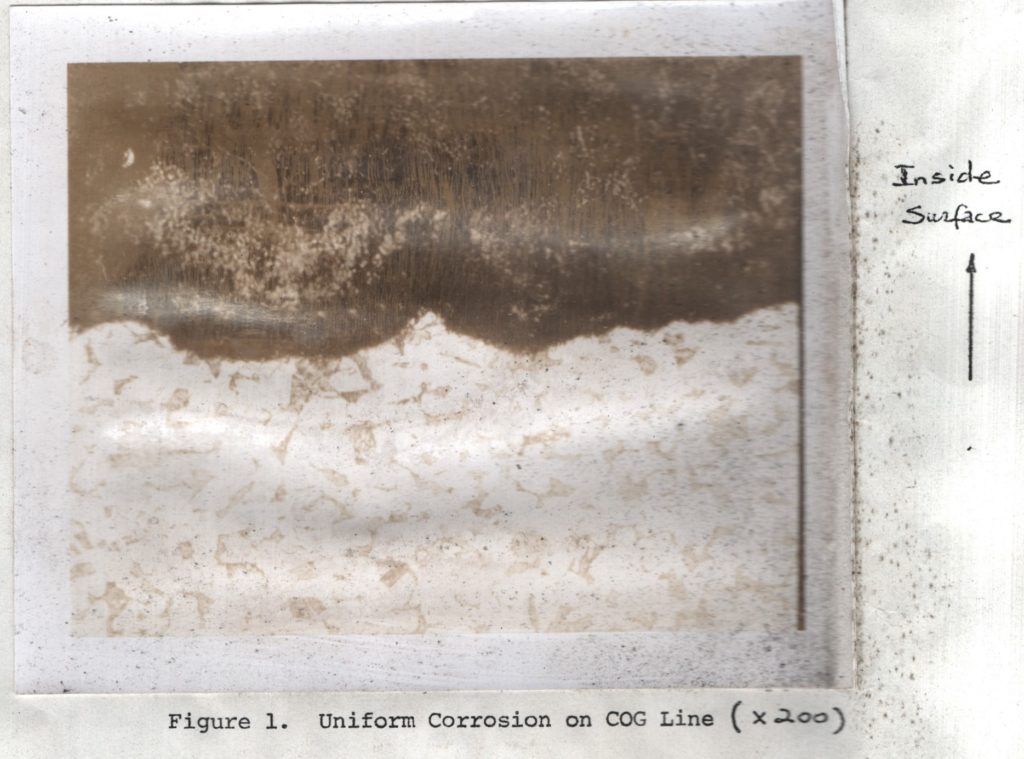

- 1976 COG line failure at furnace plant report

- includes three real photos (taped to pages)

- 1983 overhead crane inspection

- 1972 joint meeting on producitivity

- 1968 door machine accident report (great read, 2 pages)

- 1992 chicago short line RR letter

- 1988 daily maintenance reports (5 total)

- 1999 ovens group leader promotions

I wish I could say “I get a lot of questions about…” but I don’t get any questions from anyone, because no one knows/cares about what madness I am up to in some abandonded buildings. But I suppose someone might wonder what kind of mental illness I have (they haven’t figured that one out yet). And more specifically, I wanted to prove that I don’t just use a front loader to scoop up tons of documents and scan anything I find. I am very selective and that gets more and more focused as time has gone on (and my Document Archive has grown). So here is just a taste of the real deal, nasty as hell type of archeology I get up to on Saturday mornings.

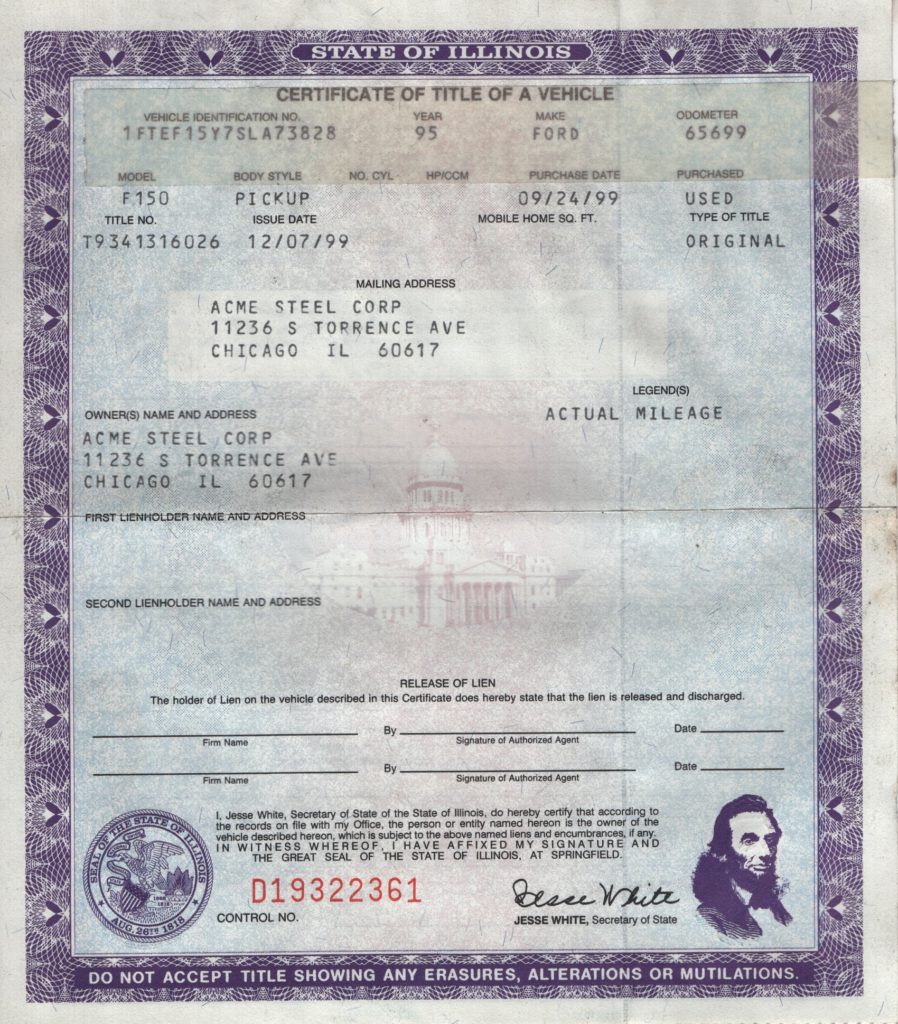

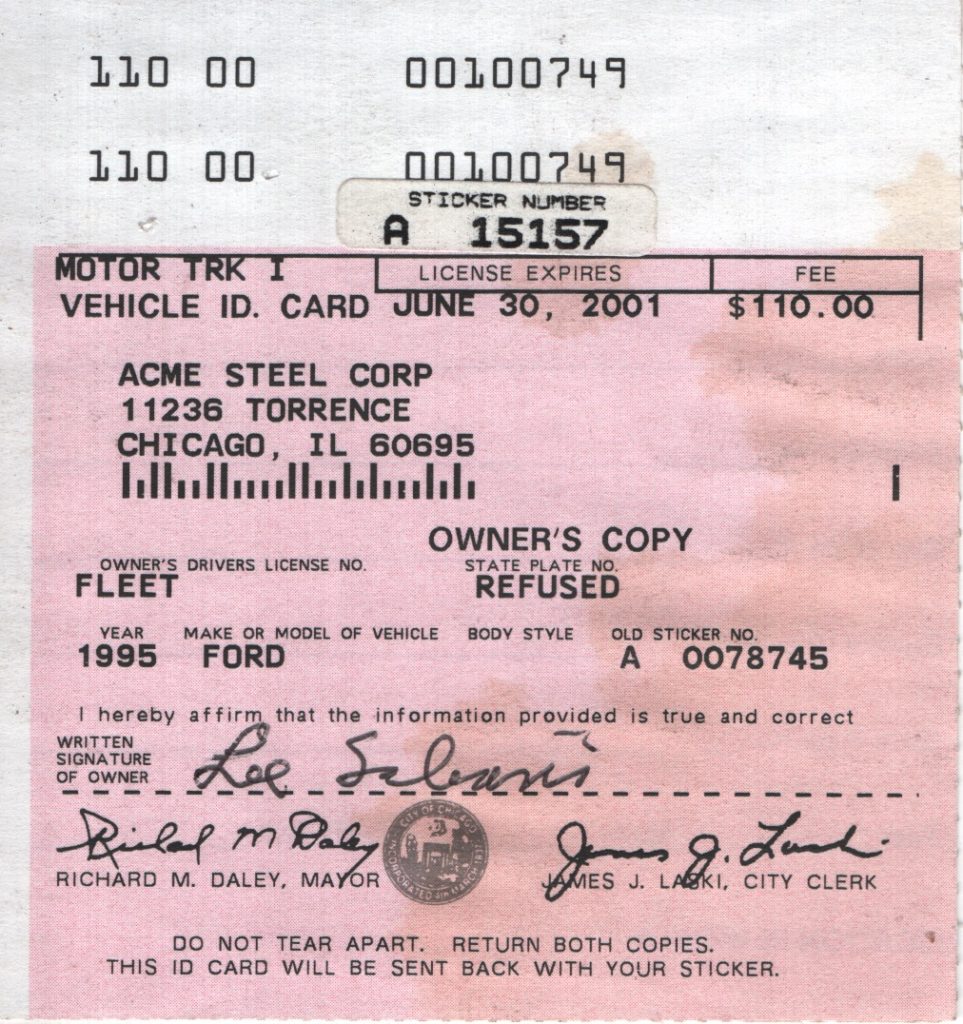

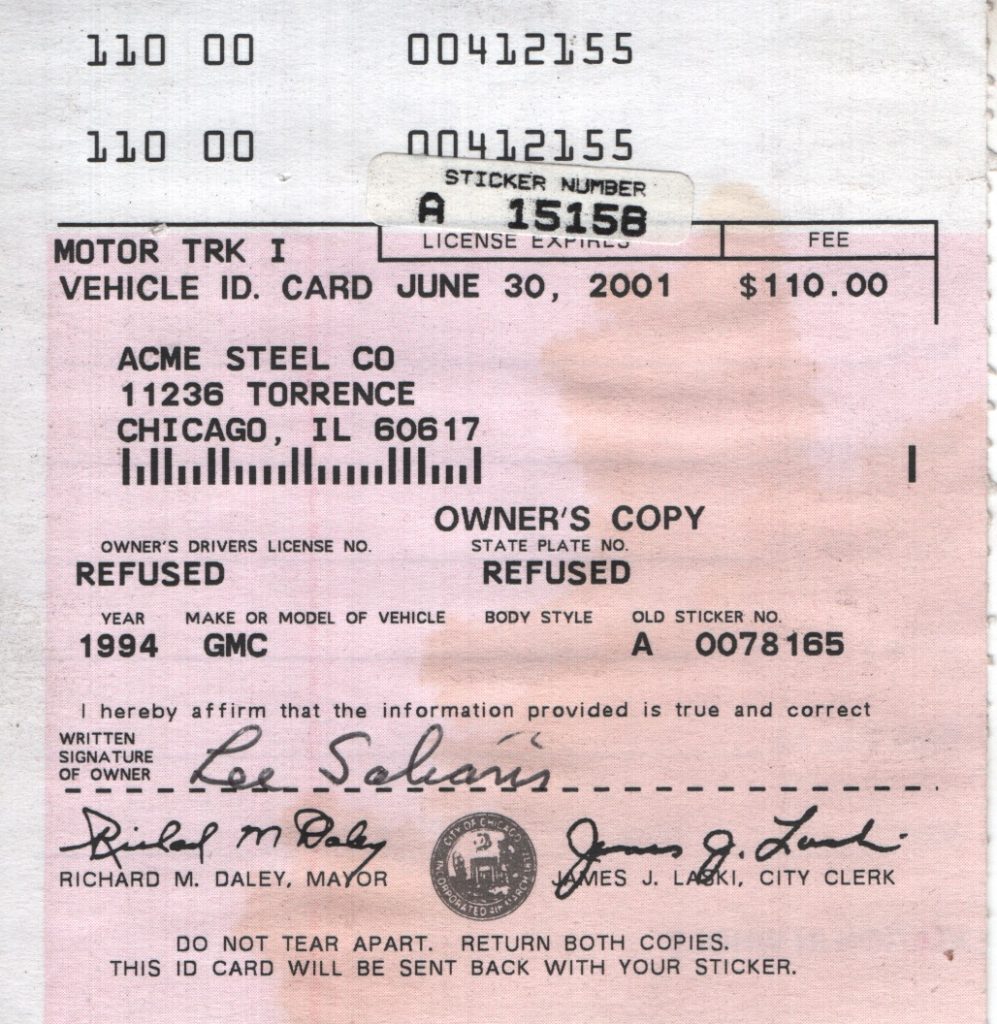

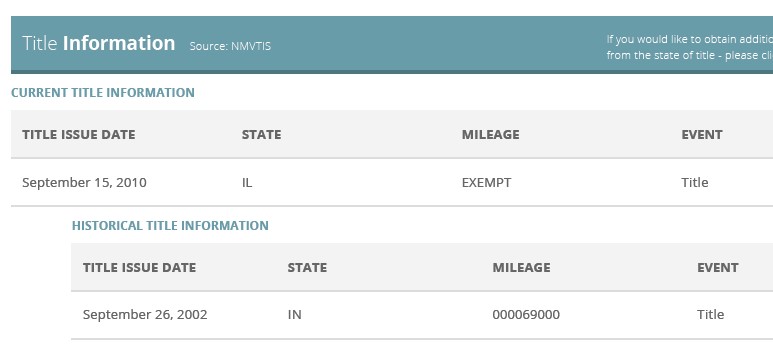

Very exciting to find a folder marked ‘truck info’. Inside – well see for yourself!

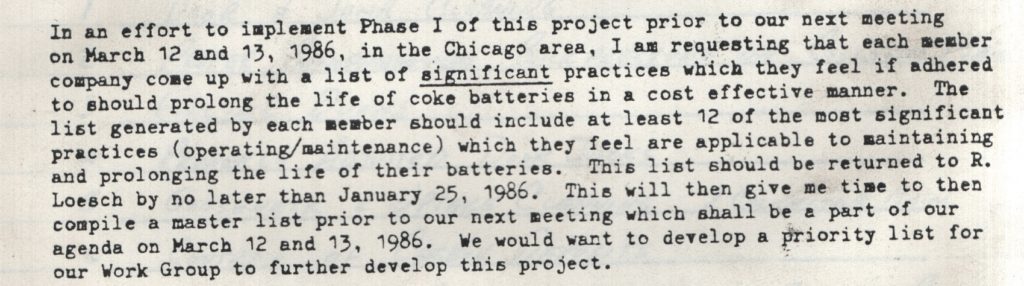

At my own job, we have to take part in groups to work on general tasks, usually sales driven things (I do not work in sales, I work in service). But we have to work together to do it. This reminds me of that very much. The division manager was a member of AISI and got stuck on one of these ‘committees’ and got assigned a task of his own:

I say this without a grain of sarcasm….but this task was promptly delegated to the #2 in charge, the assistant division manager (who’s office held these memos for the past 25 years). This is also very special because it is rare that I see memos originating from Jack, especially one which is handwritten.

But it seems that he found these 12 responses unacceptable (I must admit, they do seem a bit specific even if they are valid). So looks like Jack decided “if you want something done right, do it yourself!”

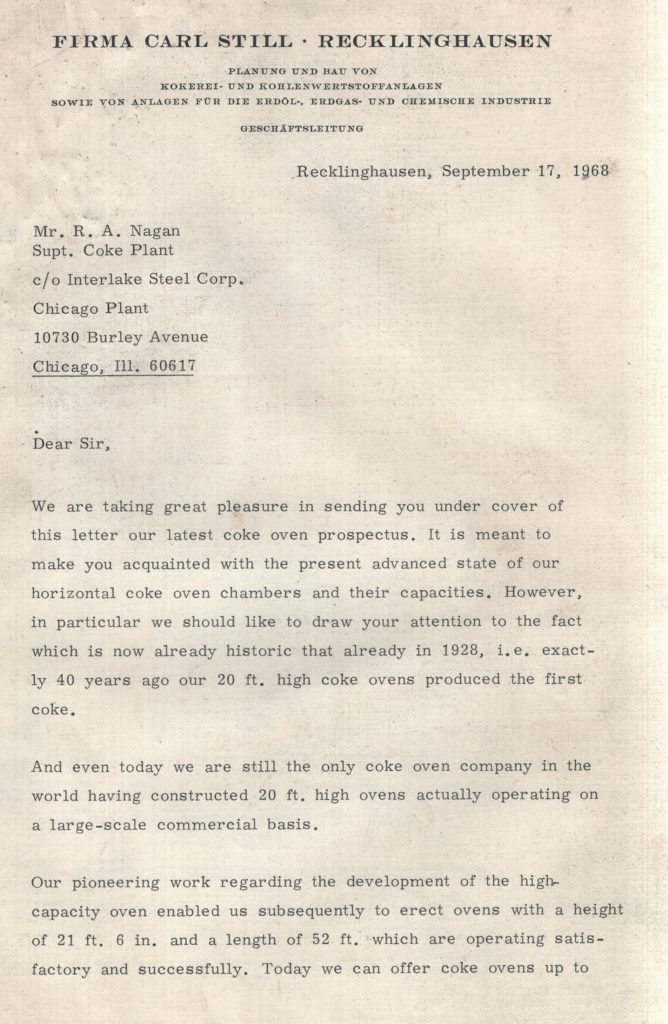

Rewinding the clock 20 years, I found this elegant letter to the plant superintendent from a German coke oven OEM. It appears that the letter was sent by the then head of the company, who was the son of the founder. Karl-Friedrich was born in 1911 and took over in the early 1950s when his father passed away. Apparently Mr. Still Sr. was mentored by Dr. Otto along side a peer you may have heard of, by the name of Koppers. The company was sold (ironically, as was Koppers) to Thyssen Krupp in the 1980s.

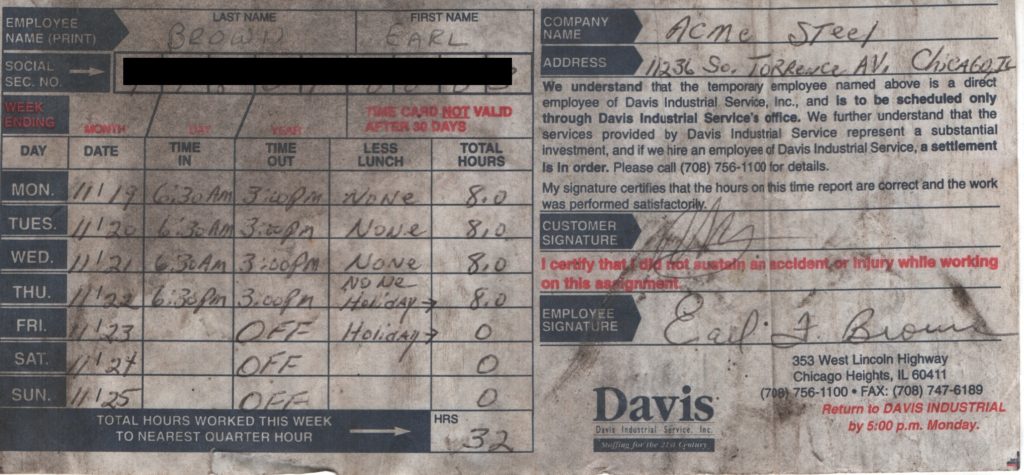

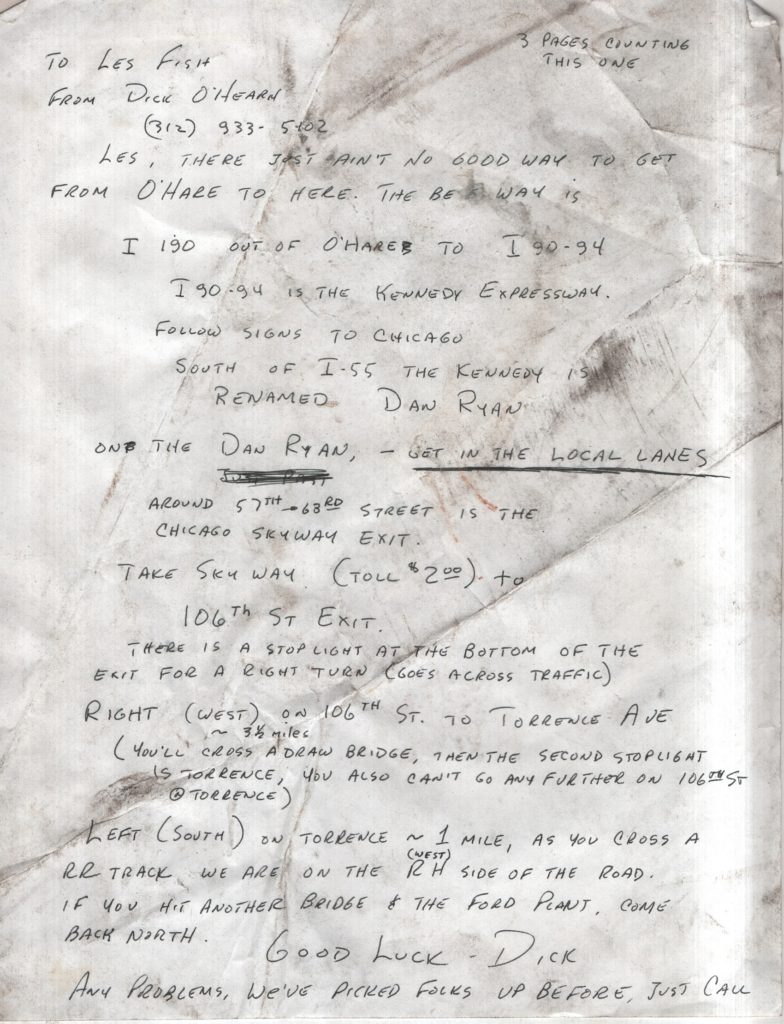

I don’t know why, but I never take the Skyway when I head down to the plant. The fact that the toll has gone from $2 to $5.80 doesn’t entice me much. Note the “…as you cross the RR track”, referencing the tracks which made up the north property border of the plant. The ties are still there, but they were removed from Torrence Ave years ago.

I had to do some research to try to figure out who Les Fish was. I took a wild guess that he was in the coal industry if he was flying in from out of state and I guess I’ve been at this long enough to hone my intuition!

I found an interesting, and dilapidated box in the small SW corner room of the BP office, where I found my plastic bin.

The name was familiar. I remembered that I had a business card from the company, but it was discarded with some others when I went through them all. But then I noticed that the header on the business cards post (which I took before I tossed some) actually was turned to that page. What are the odds?

I was going through some manilla folders and found an envelope stapled to some other papers. I carefully removed the staples with my fingernails (I’ve gotten quite good at this) and marveled at the specimen! But what was inside was even better.

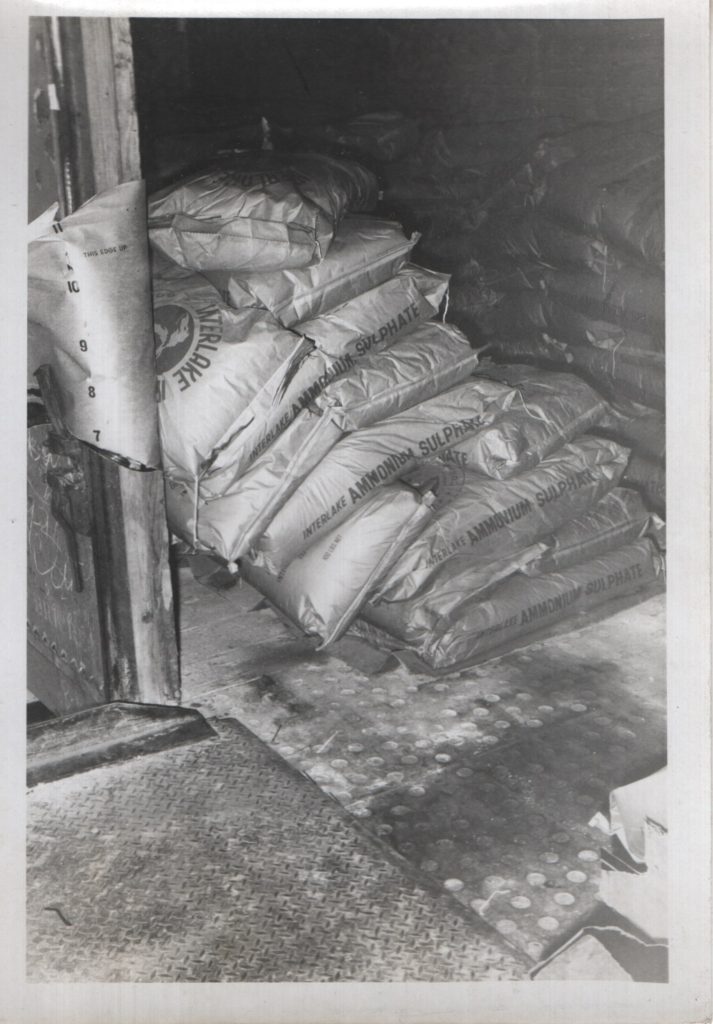

Removing ammonia from COG is imperative to any coke plant as the ammonia is corrosive and will chew up pipes and valves with a quickness. Sulfuric acid is used to bond to the free ammonia, creating ammonium sulfate which is then sold as fertilizer. So nothing shocking there. But I am blown away that apparently Interlake was acting as their own distributor, and marketing the stuff under their own name! As seen below, the photos are evidence of a load of freight (can’t quite tell if this is on a train or in a truck) that moved during transit.

[Note: the following week I found some relevant memos. Not directly attached to these photos but on the same topic]

2 replies on “I learned the truth at #17”

It’s amazing to me that in an industry which is clearly rife with an overall negative environmental impact had such a circular model in generating their own fuel and selling off byproducts as another stream of revenue. This is what companies struggle to do in 2021 and was alive and well here 50 or more years ago.

By-product coking was around even before 1900! They even sent gas to the blast furnace a mile away – gas to spare!