Acme/Interlake was more than just a coke plant. This was an integrated steel maker. That refers to a corporation that consists of a coke plant – which feeds it’s blast furnaces to make iron. That iron is then sent to a mill where it is converted into steel via a basic oxygen furnace.

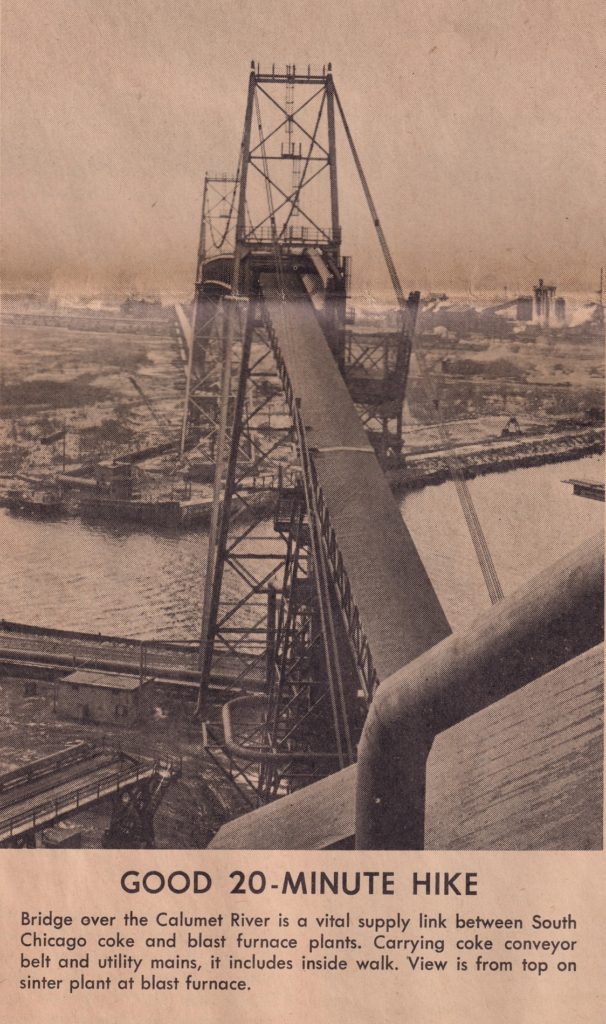

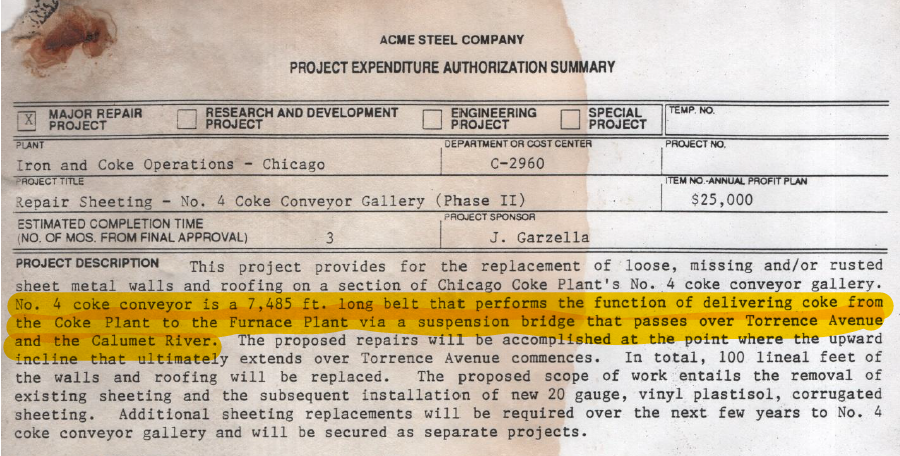

However Acme was ‘built in pieces’. These were individual, independent companies that slowly came together over a number of years via mergers and acquisitions. By 1964 all three pieces of the puzzle were intact. But while other integrated steel makers have these pieces on a single property, or adjacent properties, the geography here was a bit different. Not only would the coke have to be transported from 112th to 107th (just under a mile), it needed to travel a bit further east as well. But the Calumet River fell directly in this path so there was only one solution: a bridge.

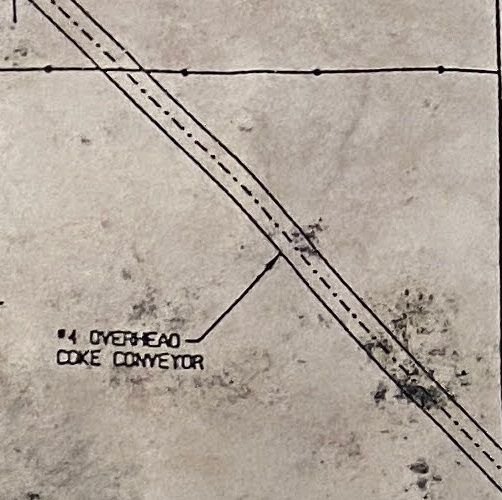

It is hard to tell when the #4 coke conveyor was built. Up until 1964 when Acme merged with Interlake, the coke plant operated as a ‘merchant’ coke plant, meaning they sold their product to various furnace plants or foundries. One has to believe that with the furnace plant across the river who did not have a coke plant, coke must have been trucked up to the 106th Street bridge for many years before the coke conveyor existed.

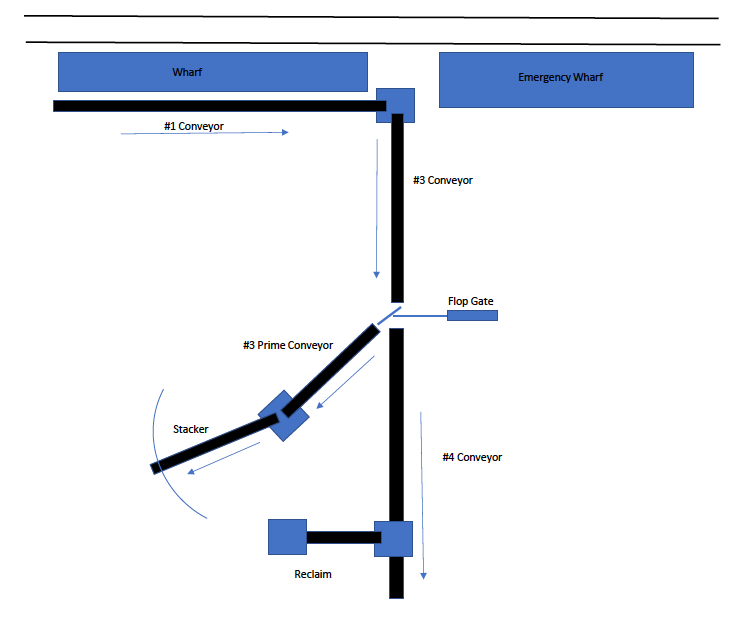

The #1 belt ran underground from the coke wharf to a transfer chute (also underground) just east of the center of the coal bunker structure. A flop gate in the transfer chute could be thrown to direct coke to the #4 belt and the blast furnace. Or to the #3 belt which fed to a stacker belt for stocking coke. There was also a reclaim hopper that via a chute could feed coke directly onto #4 belt so we could reclaim stock when needed. There was no #2 belt. That was eliminated before I started by modifying #1 to directly feed the transfer chute.

Doug Podgorny, Area Manager Ovens

8 replies on “How Acme Coke Traversed the Calumet River”

#1 belt ran south to north (parallel to the quench track) and discharged to a hopper that transferred coke to #3 belt. #3 belt changed direction 90 degrees (west to east). The flop gate was at the discharge of #3 belt. It allowed coke to discharge to #4 conveyor or dump to a short conveyor ‘#3 prime’ which discharged to the stacker belt. The stacker belt was inclined and could be moved on a rail to allow large coke piles to be created. There was a reclaim belt with a hopper that allowed a front end loader to direct stored coke back onto #4 belt. There was another element to coke transfer, the ‘emergency wharf’. It was essentially a concrete pad that allowed the quench car to dump coke if #1 belt was down. Without the emergency wharf the operation could be bottlenecked with a #1 belt outage.

Thank you for the excellent insights!

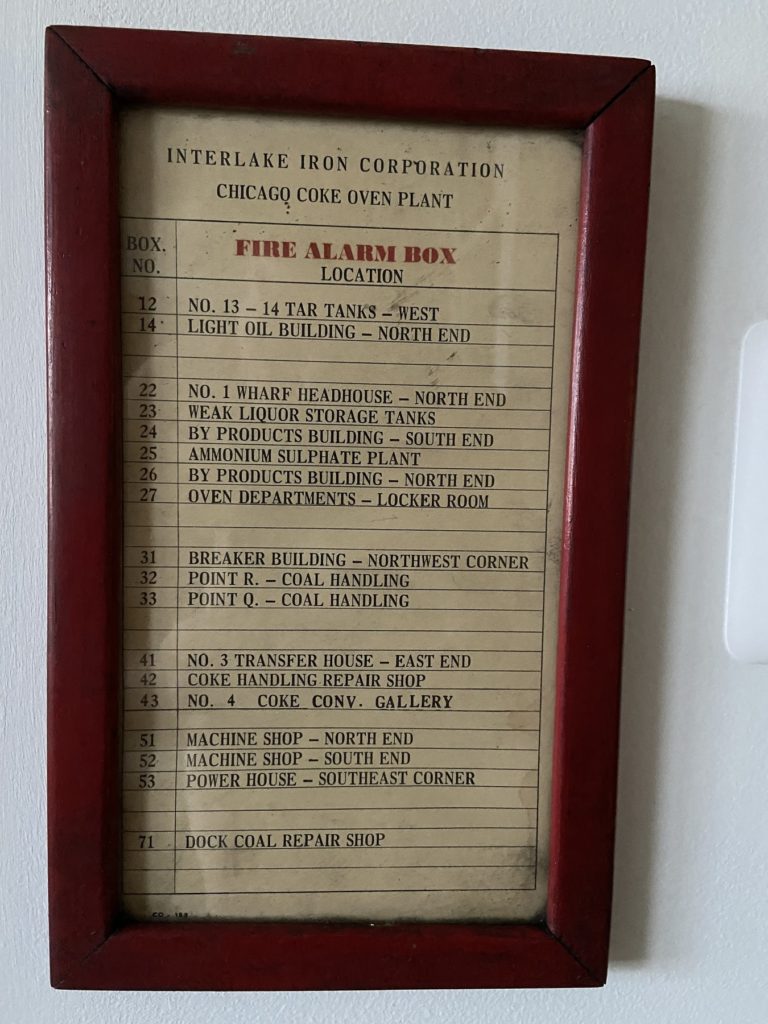

All who worked at Interlake/Acme started with an entry job. Mine was Motor Inspector. This required keeping oven machinery and conveyor systems running. To understand the coke plant conveyors (coal to coke) is something forever in ones mind. The interlocking, safety switches, full chute, speed switches, alignment, and other controls only states control that power side issues also can cripple. What’s interesting is I still can recite every belts function and designated name/number. Who is still alive that experienced coal belts that had 480 control voltage, potentially lethal, and not to code. I may be last.

Some of us are just wired (no pun intended) differently. I don’t think you could forget those technical details if you tried. I’d love to see a sketch of the #1 – 4 belts. I don’t suppose you remember the many, many belts in coal handling as well? Thank you for commenting, I always love your input my friend!

I do remember most, even the ones that were not used when rail car dumping was discontinued and coal was trucked to the coal field for Euclid reclamation.

The Acme plant in Riverdale had no connection to the furnace plant until 1964 when Acme Steel Co merged with Interlake Iron Corp. The coke plant, originally By-Products Coke Corp, was affiliated with the furnace plant, Federal Furnace Co, from the beginning in 1905. Both companies were part of Pickands Mather & Co, which consolidated into Interlake Iron Corp in 1929.

you are absolutely right, this was my misinterpretation of a reference from the old furnace plant website

thanks for pointing out my glaring error – it is now fixed!

I walked across the conveyor on my last there in 1978.

It was long way down

There is also a tunnel under the river, that has been flooded since the 60’s