I have been lucky enough to find a total of three lidman training guides. The most recent, was a giant 50 page binder, complete with quizzes for each chapter and an answer page. I first watched the video above a couple months ago. Even at less than a minute long, I am fascinated. But after studying the 50 page binder I found last weekend, I see that there is much more to the job than opening and closing lids, and sweeping up.

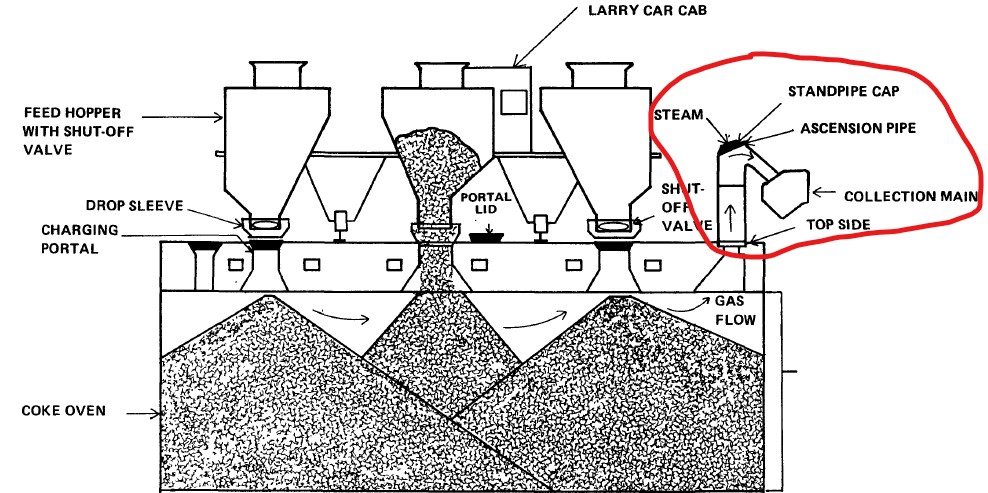

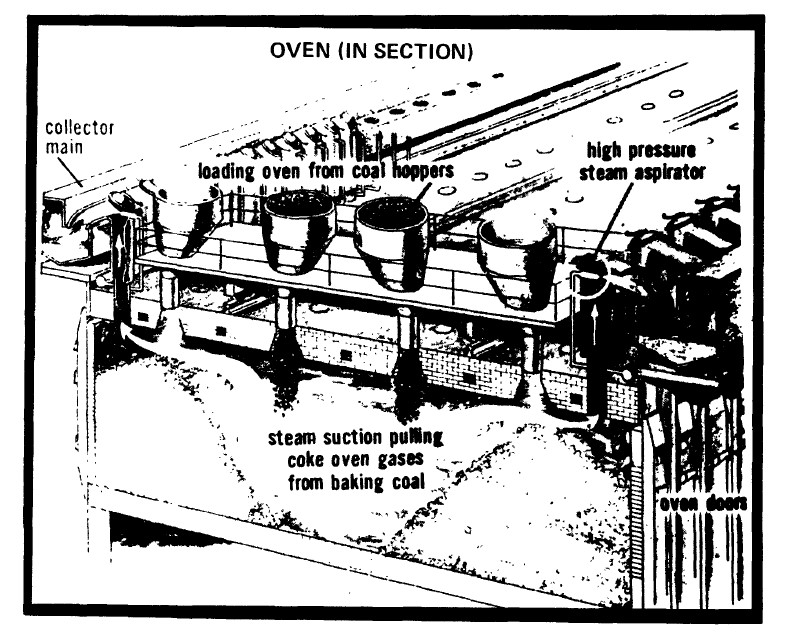

You can’t have guys popping the lids off of ovens full of 2000C coke which would burst into flame and destroy itself, endanger personnel with heat and fire and emit loads of toxic fumes. A systems of standpipes use steam to keep the heat and flames at bay. And all of this and more falls to the lidman to maintain.

The standpipe that draws the toxic gas to the by product plant contains the steam jets used to draft the gas away from open lids. But both the standpipe itself and the steam jets get regularly filled with carbon deposits, so keeping the areas clean enough to function well also falls to the lidman. In this 20 minute video titled “Gooseneck cleaning”, only about 90 seconds is on the battery top. The rest is a quench car catching hot coke and door cleaning. I can’t embed the video, which is just as well but here is the one shot of someone cleaning the gooseneck:

An oven battery is a terribly dangerous thing, filled with extreme temperatures and toxic gas. The lidman’s responsibility is to keep those elements at bay for the good of himself, the coke and the environment at large by checking and maintaining the systems already in place.

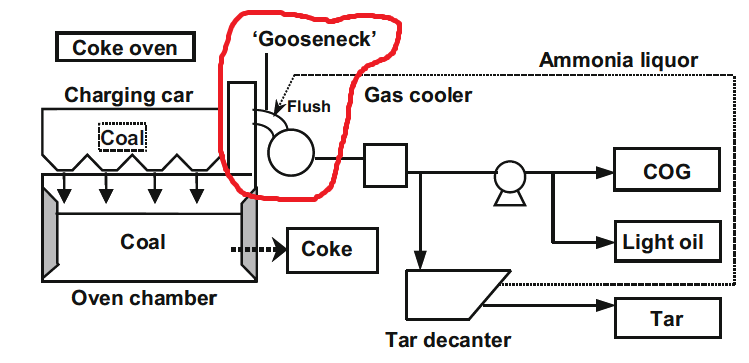

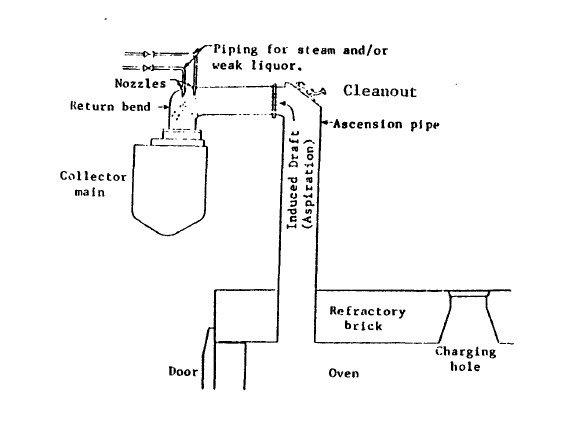

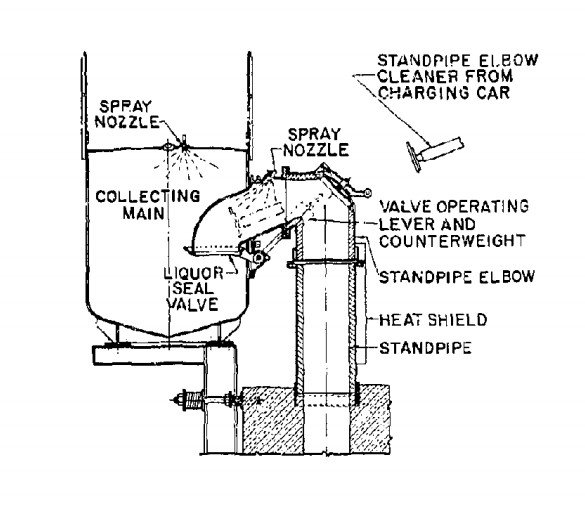

So much is still unclear to me and I’m struggling for better illustrations of the system. The BP process isn’t relevant to me in trying to understand the battery itself but at least this shows the standpipe with gooseneck. It does not illustrate how steam works into the system but I think I have it.

The whole system relies on having an empty oven adjacent to the one about to be charged with fresh coal. If there are X of charging lids for the oven, there are X+1 total, as the bonus lid is used for draft the COG/heat/fire temporarily into the empty oven.

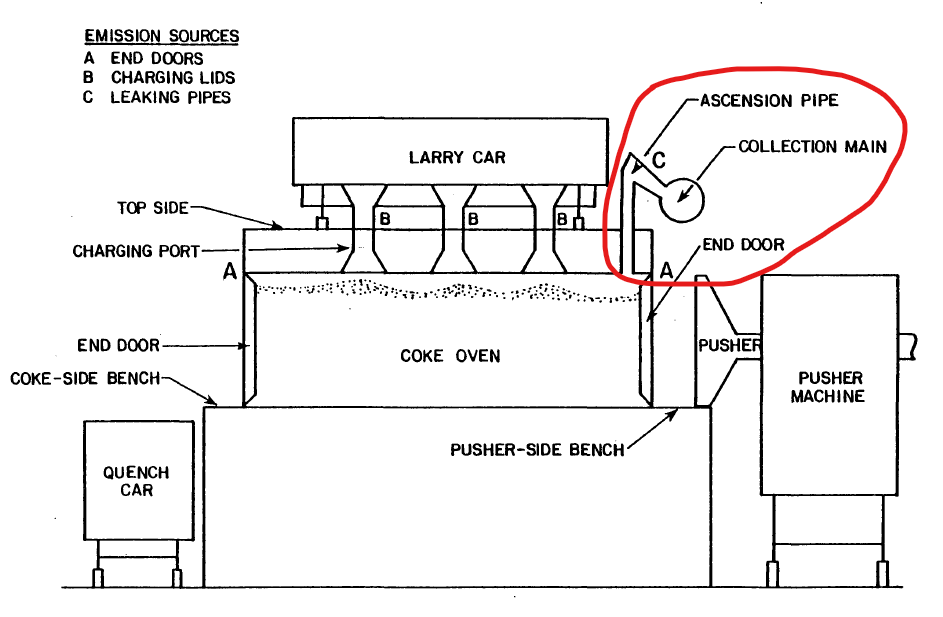

Normally, the coke oven gas leaves the battery via the standpipe (‘ascension pipe’), gooseneck (where it is cooled with ‘liquor’, a weak ammonia solution) and collector main en route to the by-product plant. When preparing for charging, steam is connected to the standpipe and sent backwards INTO the oven. The original Wilputte patent from 1944 actually explains it very well, wish I had found this earlier on.

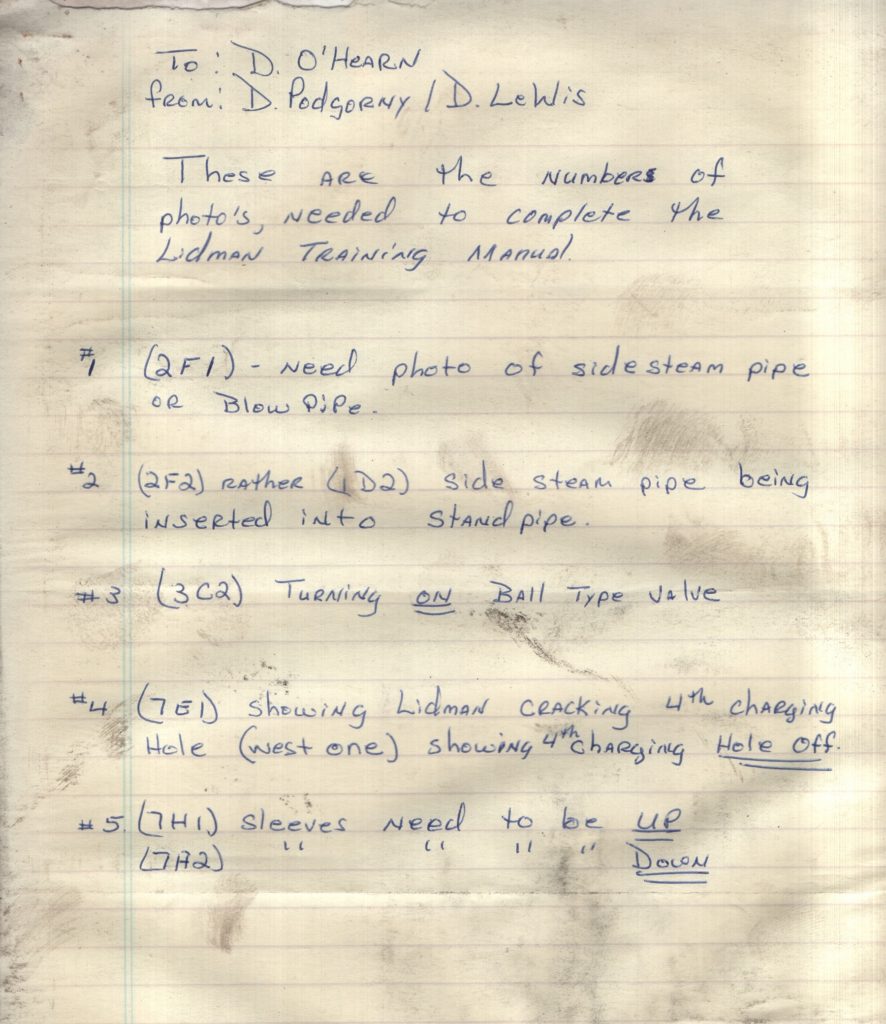

The first two training references I located are more of just bullet points and don’t go into much detail. The newest however is quite specific. Disappointing that photos are referenced throughout but are not included. It seems they never were, perhaps they came as a separate manual or were shown on an overhead projector.

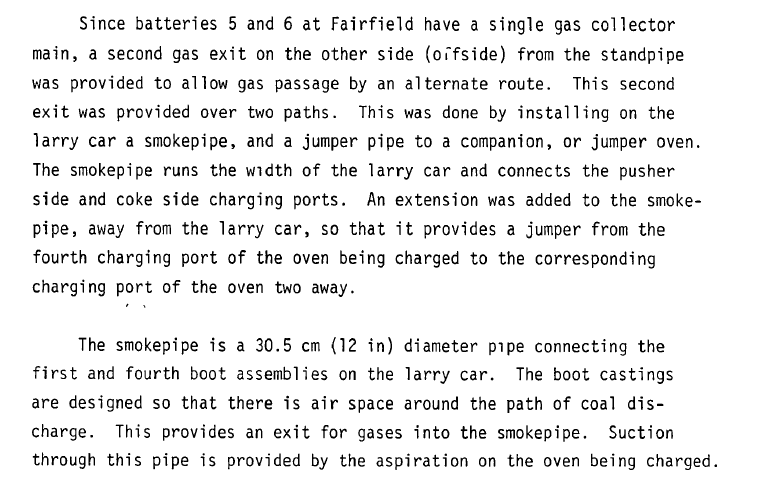

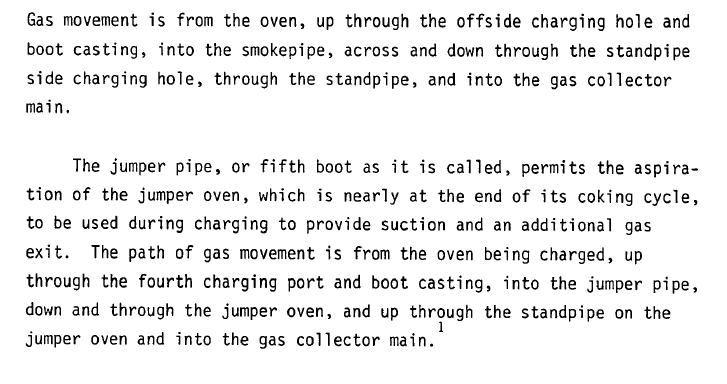

I had some trouble understanding the U-pipe and it’s use. I found this explanation which makes it a bit more clear. The U-pipe is referred to as a ‘smoke pipe’ and the assist oven called a ‘jumper oven’, if I am reading this correctly. The below screenshots are from a report at US Steel, Fairfield Alabama (1976).

Lastly I found some excellent videos from another (also, sadly, now closed) coke plant in England. I can identify a few differences between their battery and Acme’s (they have four charging ports while Acme has three) but this really helped me a lot. You can watch them here and here. I took some screenshots that were very useful to me.

My understanding:

- Damper off oven (isolates oven from collector main?)

- Open riser cap (to prevent pressure from building?)

- Connect side steam pipe to stand pipe (with steam ‘off’, to create a draft to draw heat/flames away from the lids which are about to be opened)

- Crack lids and inspect

- Replace all lids except one

- Connect side steam pipe to stand pipe (with steam ‘on’, to keep heat away from gooseneck)

- Inspect gooseneck

- Turn off steam/ream steam jets

- Inspect uptake of collector main

- Push oven

- Disconnect side steam pipe

- Open all lids

- Connect steam to assist oven (turn on just before larry car arrives)

- Open lid #4 on assist oven

- Connect U-tube between lid #4 on charging and assist oven

- Oven is charged/leveled

- Replace lids on charging oven

- Disconnect U-tube

- Replace lid #4 on charging oven

- Replace lid #4 on assist oven

- Open charging lids and sweep up (one lid at a time)

- Add slurry to four charging lids and one assist lid

- Lock riser cap

- Turn off steam on assist oven

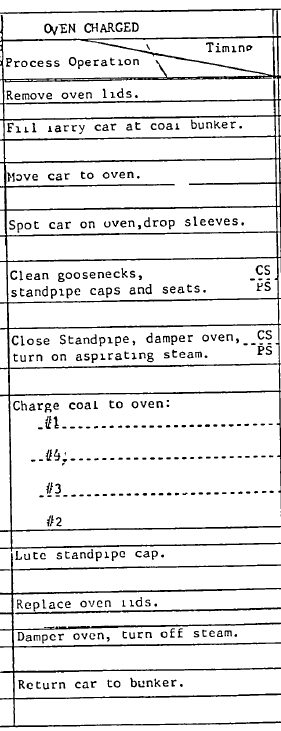

Here is a very simple outline similar to my own, missing some details of course:

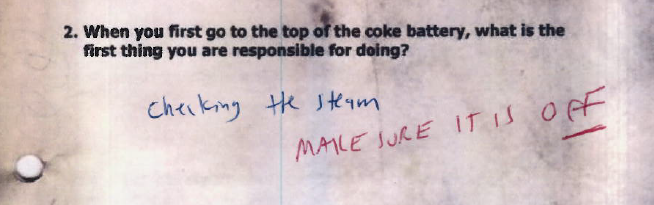

I lacked most of the above info BEFORE I sat down to take the quiz but I muddled my way through it.

I took the quizzes more or less as ‘open book’, but some parts were still unclear. So I checked my quiz afterwards (in red ink of course). With some photos (or far more thrilling, hands on experience) I think I’d do all right.

I’d be a pretty sad lidman if you put me on a battery this morning most likely and I’d have more questions than a three year old, the kind that tugs on your shirt and asks “why?” to everything you say. I’m a few years older than three but I’m an apt pupil and don’t have to be told twice. Now as soon as I can get some fuel for my time machine and an apartment in Hegewisch, I’ll take a shot at it!